CUTLAM®4.0

The CUTLAM®4.0 is designed especially for manufacturing companies with high standards who are looking for high-quality and reliable equipment for heavy-duty use with a great cutting capacity.

-

Wheel Ø300 to 400 mm

-

Rotational speedfrom 1000 to 4000 rpm

-

Max cutting capacityØ 154 mm

-

Dim. W x H x D818 x 1802 x 1280 mm

The CUTLAM®4.0 is a pedestal-mounted single-block machine with an integrated recirculation/decanter tank. The wheel’s vertical descent can be controlled automatically (oleo pneumatic) or manually using the joystick. The maximum cutting descent is 240 mm.

Adapted for intensive use on heavy components, the CUTLAM®4.0 is fitted with a powerful 5.5 kW motor.

The wheel’s speed is adjustable from 1000 to 4000 rpm, the feed speed is adjustable. 2 cutting modes are available: sequential automatic with adjustable frequency or continuous.

An end of cycle sensor shuts off the machine and automatically raises the wheel after each operation.

The controls are easy to use and intuitive: they are centralized on the 5.7’’ arm-mounted touch-screen.

The cover opening clears 3 sides, guaranteeing easy loading of heavy or bulky parts. Removable gates to the left and right enable you to cut long bars.

The wide cast-iron clamp bench has 6 T-longitudinal grooves and 5 transversal grooves, and as an optional extra may be made mobile along the X and the Y axes.

The multi-point hose over the wheel and part ensures optimum cooling for high-quality cuts and consistent results.

In the standard configuration, the work area is illuminated by a adjustable spotlight, and an external shower head is provided for cleaning the cutting area.

In order to optimise your equipment according to your needs, a variety of accessories and optional extras are available.

Design and advanced technology

Technical characteristics and equipment

*space under disc

Option

-

Positioning laser60 CT403 00

Machine variations

-

Table with manual transversal displacement (X axis) of a 120 mm stroke60 CT40A 10

-

Table with manual longitudinal displacement (Y axis) of a 180 mm stroke60 CT40A 20

Downloads

Technical data CUTLAM®4.0

Cut-off wheel Ø | 300 to 400 mm |

Shaft Ø | 25,4 mm |

Standard flanges Ø | 100 mm |

Max cutting capacity | Ø 154 mm or 145 x 160 mm or 90 x 275 mm (with a Ø 400 mm disc) + right and left opening for long parts) |

Passage under the disc | 190 mm (with a Ø 400 mm disc) |

Vertical movement | Manual |

Lubrification | Recirculation system, 140 litres, on casters Cleaning system integrated, with a shower head outside of the cutting chamber |

Motor power | 5,5 kW |

Rotational speed | Variable, from 1000 to 4000 rpm |

Arm speed advance | 5 to 200 mm/min during cutting |

Table | Double grooved treated cast iron, 400 x 400 mm |

Type of groove | T groove 12 mm (6 longitudinal, 5 transversal) |

Lightening | LED |

Protection | Cover with locking system |

Body | Steel coated with epoxy paint |

Pneumatic feeding compressed air | 6 bars filtered 5 µ |

Electrical power | 6 kW cumulative |

Electrical consumption | 24 Ah |

Voltage | 400 Volts – 50 Hz (three-phase) |

Dim. W x H x D | 818 (+ 300 mm with control panel) x 1802 x 1280 mm |

Weight | 650 kg |

Reference | 60 CT40A 00 |

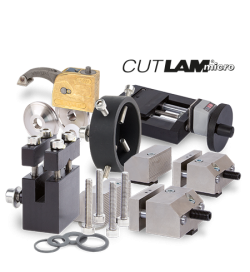

Available accessories

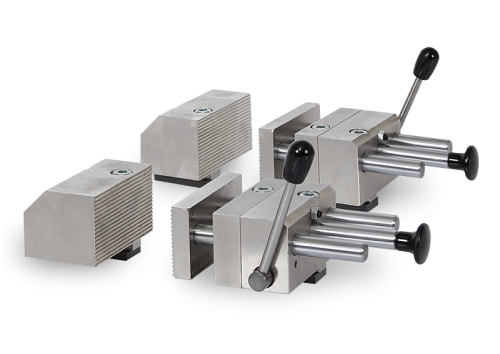

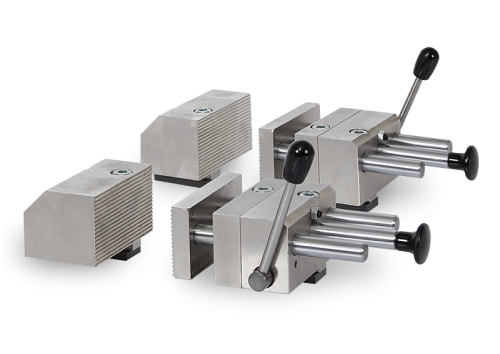

Double vice with fast tightening system

(left and right side of the wheel)

2 x 2 elements vice, without sole, to obtain maximal length clamping.

Jaws: W 80 x H 45 mm

T-slot 12 mm screw included.

Left and right levers.

Double vice with fast tightening system

(left and right side of the wheel)

2 x 2 element vice, without sole, to obtain maximal length clamping.

Jaws: W 80 x H 70 mm

T-slot 12 mm screw included.

Left and right levers.

Double vice with screw tightening system

(left and right side of the wheel)

2 x 2 element vice, without sole, to obtain maximal length clamping.

Jaws: W 80 x H 45 mm

T-slot 12 mm screw included.

Left and right levers.

Universal clamping KOPAL 61

Lift for KOPAL 61

Long cam for KOPAL 61

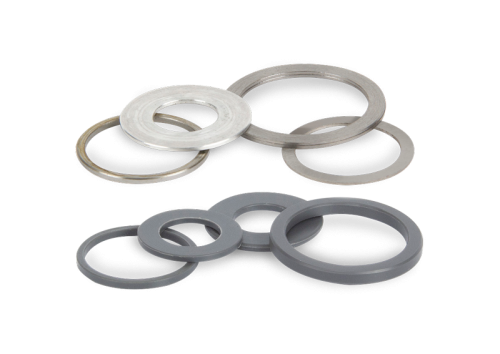

Steel & PVC adaptor rings for cut-off wheels

- Steel Ø 32 x 25,4 mm (5 units) – 60 00373 90

- PVC Ø 32 x 25,4 mm (5 units) – 60 00374 90

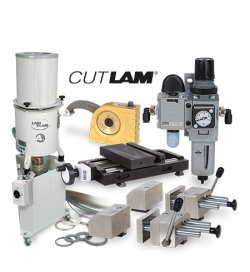

Oil mist extraction device A1

The LAM PLAN vaccuming system extracts the “polluted” air inside the cutting chamber of your cutting machine.

A special multilayer filter will stop the smallest polluting particles, thus preventing their dispersion into the atmosphere. The cutting fluid, in the liquid state, is returned to the cutting machine recirculation tank to be reused. (An evacuation is provided for this purpose on the vacuuming system). A cartridge post-filter, located above the suction system, ensures a high filtration level, up to 99.97%. An adapter part (LAM PLAN code 60CT20820) is provided to adapt the suction hose to the canopy of the LAM PLAN cutting machine. The vacuuming system is mounted on a trolley with wheels, allowing an easy positioning. A drain valve, located in the trolley, collects the condensate.