-

Ø plate capacity250 to 300 mm

-

Plate rotation speed20 to 650 rpm

-

CapacitySample size 6 X Ø 40 mm

& 6 X Ø 50 mm -

Programming60 storable programs

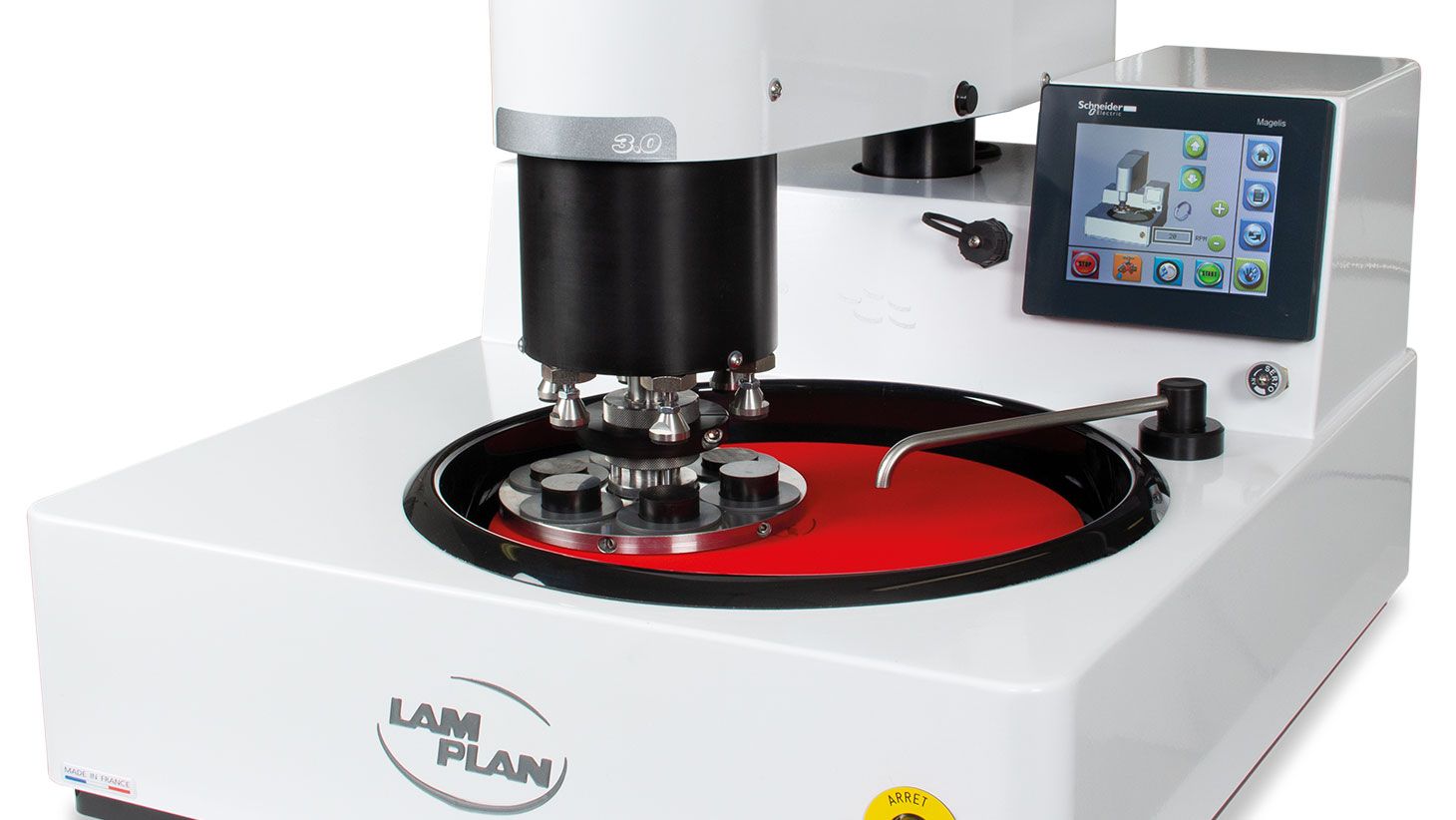

MASTERLAM®3.0

This machine has all the functions that make the MASTERLAM® range outstand and on this model a specific new combo-head.

The MASTERLAM®3.0 is the metallographic polishing machine without concession. Polishing can be carried out with central pressure or individual pressure and can be equipped with a stock removal measuring system.

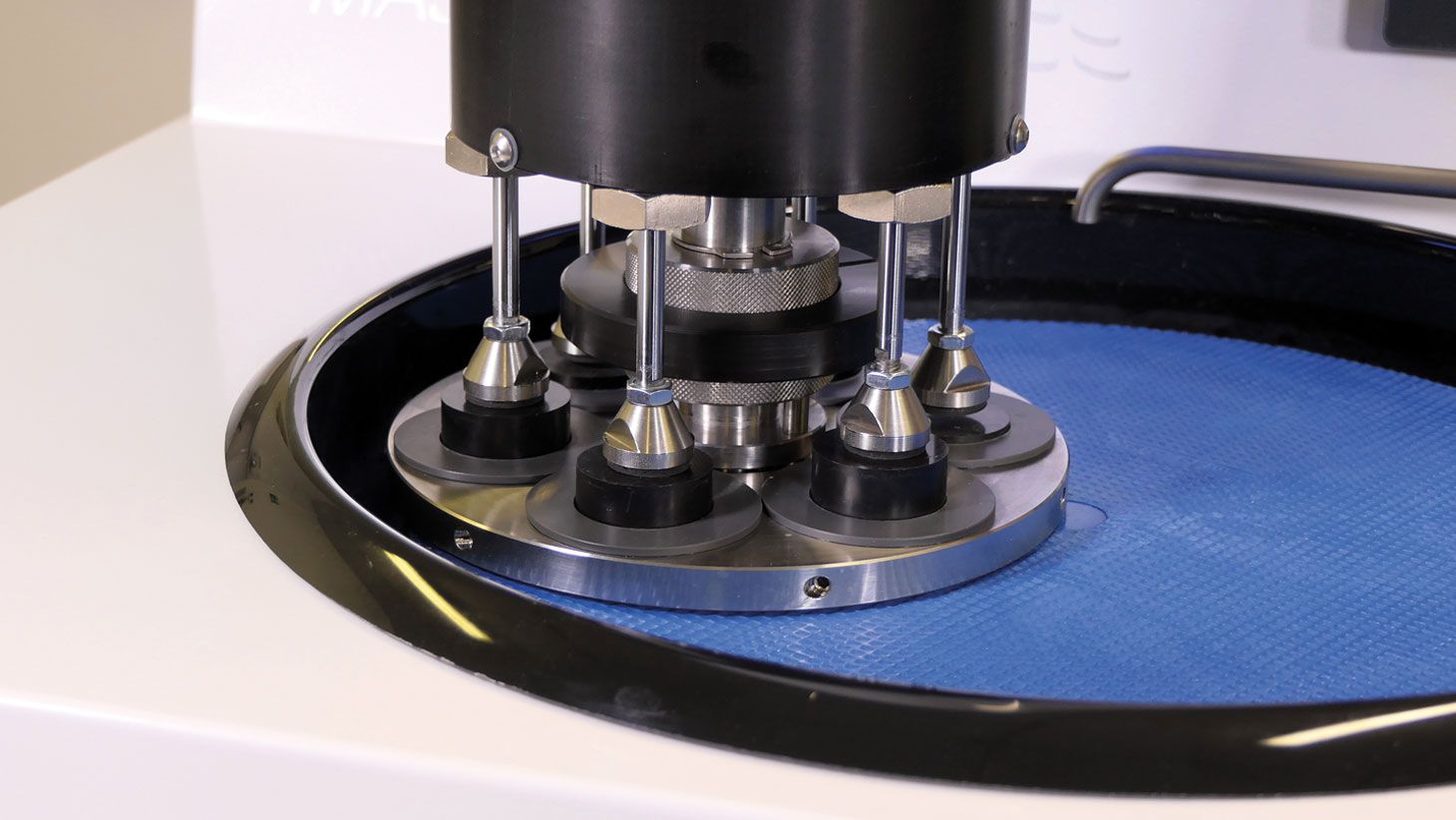

The MASTERLAM®3.0 is based on the same technology as the MASTERLAM®1.0 with, in this configuration, a powerful central and individual pressure head equipped with 6 pistons. Changing sample holders is quick and the pressure mode is controlled directly on the screen without having to touch the head, thus, you can switch from one pressure mode to another in a few seconds.

Central pressure mode

Individual pressure mode

Design

and advanced technology

The MASTERLAM®3.0 is a high-performance machine intended for intensive use such as in-production inspections.

Technical characteristics

and equipment

Options

-

Stock removal control system60 ML30S C0

Downloads

Technical data MASTERLAM®3.0

Plate capacity | Ø 250 to 300 mm |

Body | Steel coated with epoxy paint |

Bowl | Removable resin bowl for easy cleaning |

Controls | Touch screen (5,7“) |

Plate rotation speed | Variable from 20 to 650 rpm Bidirectional rotation |

Head’s speed | Variable from 10 to 150 rpm Bidirectional rotation |

Applicable load | 5 to 400 N central pressure 5 to 100 N individual pressure |

Capacity | Sample size 6 X Ø 40 mm Sample size 1 – 6 X Ø 50 mm |

Workspace lightening | LED |

Water inlet | Removable pipe, with flow rate adjustment and safety solenoid valve |

Programming | 60 storable programs, USB connector to backup programs and Ethernet port for networking |

Cumulative machine power | 1.1 kW |

Voltage | 230 V – 50 Hz single phase |

Pneumatic feed | 6 bars |

Dim. W x H x D | 550 x 670 x 580 mm |

Weight | 85 kg |

Reference | 60 ML300 00 |

Available accessories

Dosing unit DISTRILAM®

The automatic dosing unit DISTRILAM® is directly controlled via the touch screen on the machine through a RS 232 connector. It is instantly recognised by all the MASTERLAM® polishing devices as the control program is already programmed in the machines.

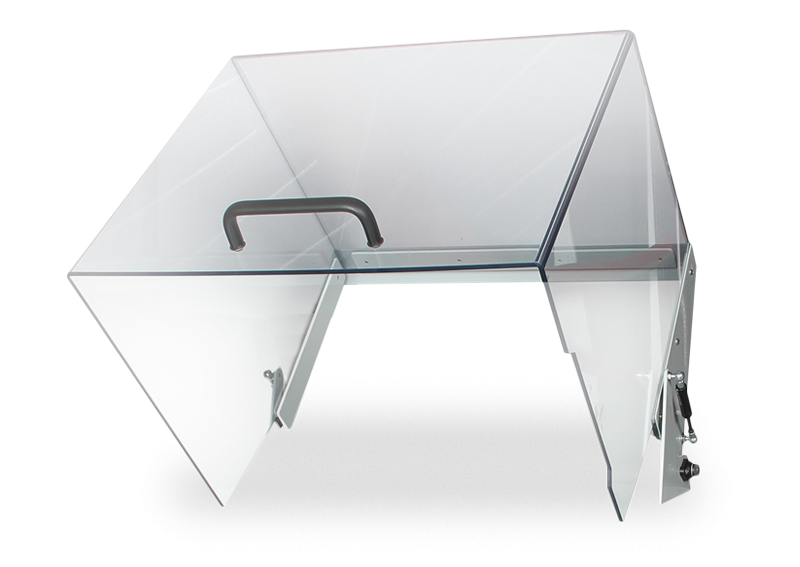

Transparent protective housing

The secured housing is a totally transparent protection compatible with the full range of MASTERLAM®.

Its opening stops all movements of the machine*, it offers an integral protection complying with the 2006/42/ CE and 2004/108/CE standards. The housing’s design preserves the accessibility of the plate and does not clutter the workspace.

The touch screen is located outside of the secured zone; therefore, the commands are permanently accessible.

For the MASTERLAM®1.0 and 3.0 the touch screen control panel is located on the right, a 195 mm space needs to be foreseen in addition to the machine width.

*However, the transparent secured housing authorises the plate rotation in the manual mode.

Required space for the MASTERLAM®1.0, 2.0 and 3.0:

Width 770 mm – Height 910 mm

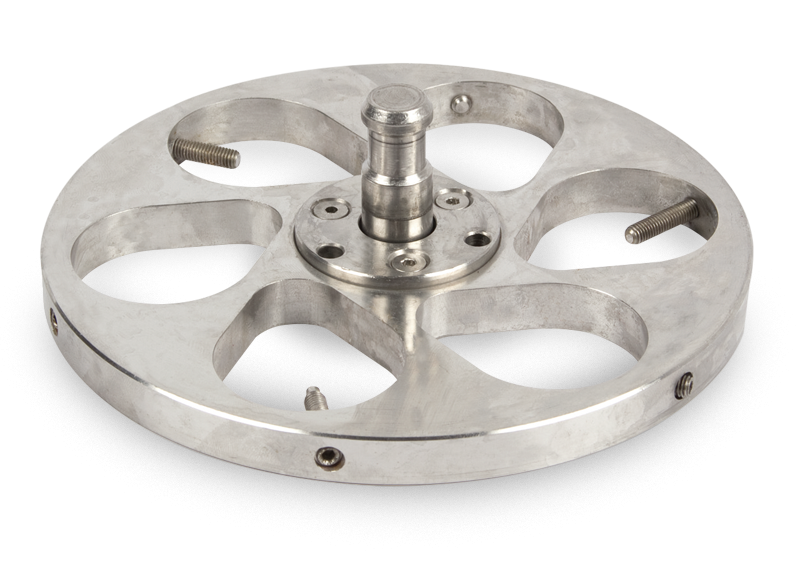

Aluminium plates

- Aluminium plate Ø 250 mm – 08 8270300

- Aluminium plate Ø 300 mm – 08 8270400

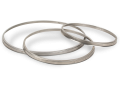

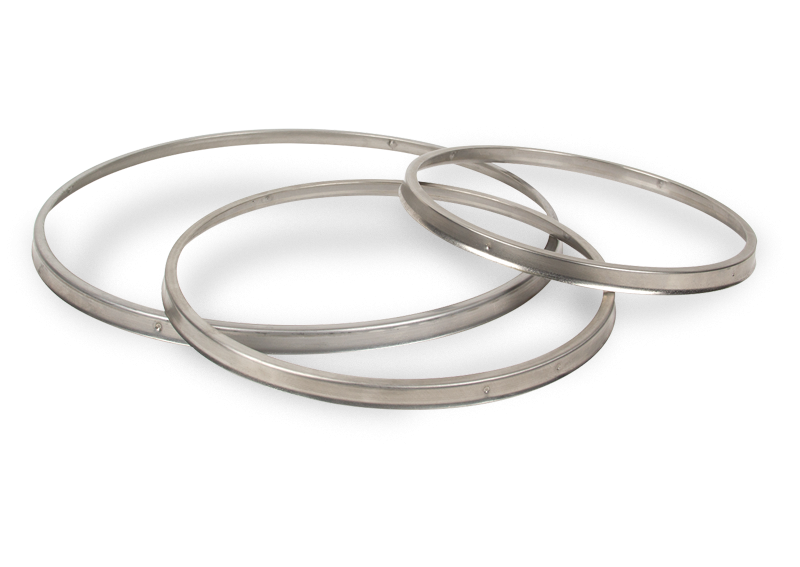

Metal clamping rings

- Metal clamping ring Ø 250 mm – 60 SL00490

- Metal clamping ring Ø 300 mm – 60 SL00690

- Metal clamping ring Ø 305 mm – 60 SL00790

Tank reducers

- Tank reducer Ø 230 mm – 60 ML08290

- Tank reducer Ø 250 mm – 60 ML08190

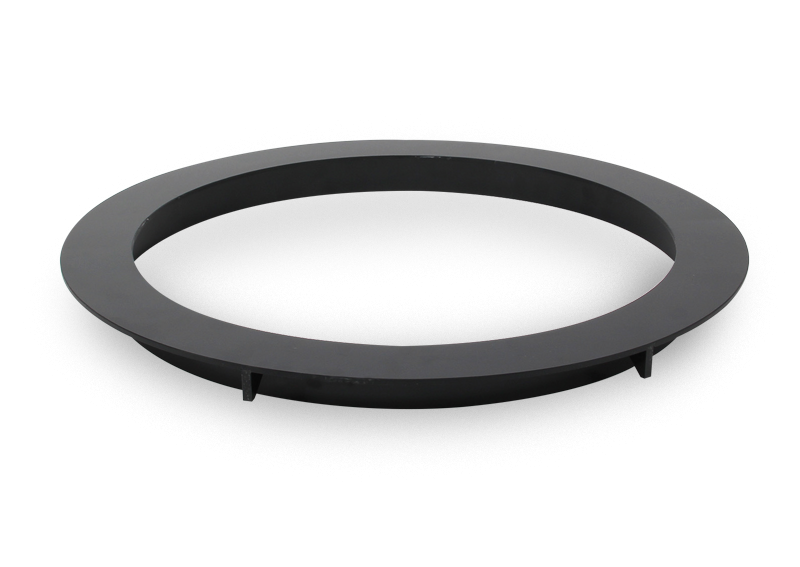

Anti-splash ring

CP sample holder

- PC Ø 160 mm with 6 x Ø 20 to 40 mm water drop cells

06MLC1000 - PC Ø 160 mmwith 9 x Ø 30 mm water drop cells

06MLC3000 - PC Ø 160 mm with 6 x Ø 40 mm water drop cells

06MLC4000 - PC Ø 160 mm with 5 x Ø 50 mm water drop cells

06MLC5000 - PC Ø 160 mm with 3 x rectangular 40 x 70 mm water drop cells

06MLC1200 - PC Ø 160 mm with 6 x rectangular 25 x 34 mm water drop cells

06MLC1400

IP sample holder

Ø 160 mm with 6 x Ø 50 mm water cells

Sample holder for irregular parts

Ø 160 mm central pressure sample holder for eccentric restriction of non-embedded complex geometric parts.

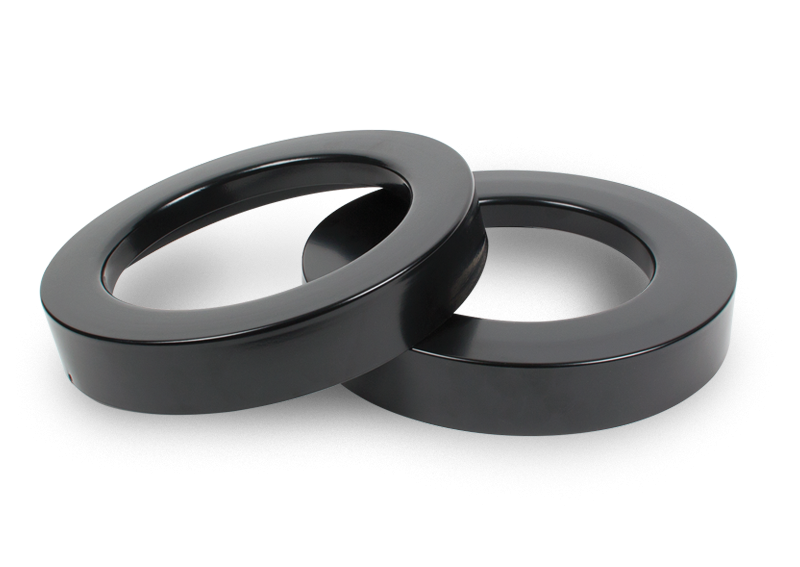

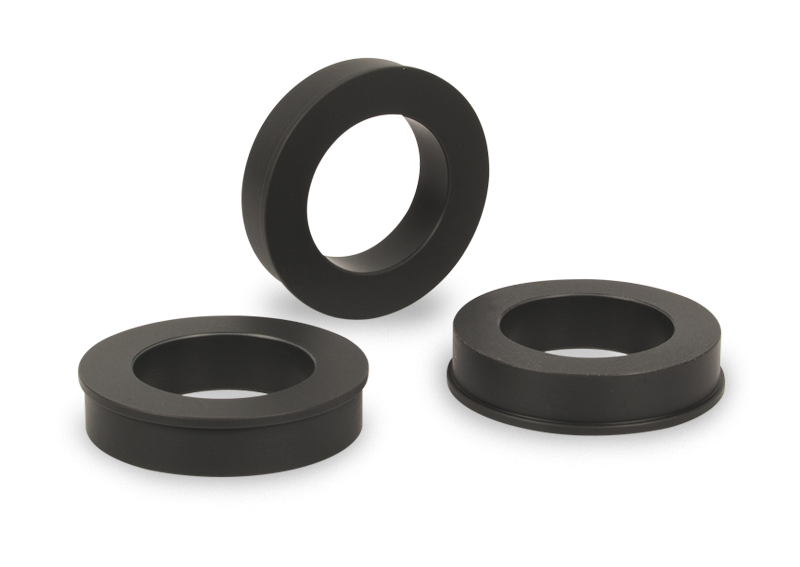

Reducer rings

- Kit 6 x Ø 40 mm reducer rings – 06MLIK500

- Kit 6 x Ø 30 mm reducer rings – 06MLIK200

- Kit 6 x Ø 25,4 mm reducer rings – 06MLIK110

- Kit 6 x 1-1/4″ reducer rings – 06MLIK310

- Kit 6 x 1-1/2″ reducer rings – 06MLIK410

Levelling plate for CP sample holder

Ø 160 mm – 3 mm depth

Sedimentation 60 L tank

With pump controlled by the machine.