Research, consulting & training

Research

Research and development have been at the heart of our activity for more than 50 years. LAM PLAN is continuously innovating and could provide for numerous contributions which revolutionised on several occasions the polishing technologies.

LAM PLAN is a leader in the polishing sector thanks to this capacity to innovate and the quality of the resulting products.

We place this unique expertise at the service of your projects.

Our design & engineering department and our test laboratory regularly work hand-in-hand with our customers to find the solutions to their polishing problematics.

- Fine-tuning of processes

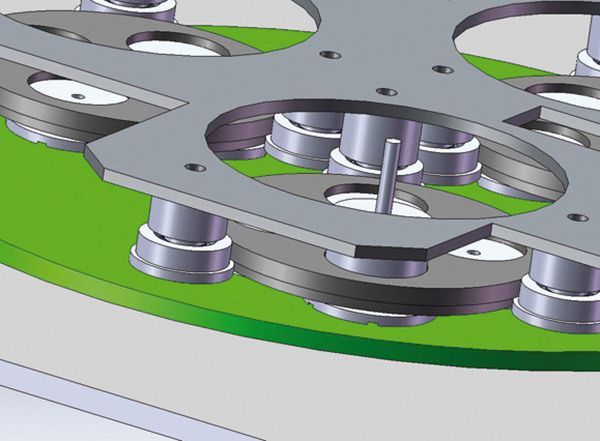

- Customising the equipment

- Development of fixing and clamping systems

- Design of special machines for in-production lapping / polishing

Consulting & Services

General customer foolow-up process

Analysis of the needs

Technical aid to elaborate your specification, deepen and/or upgrade your knowledge.

Research & Development of solutions

Identification and highlighting of the technical improvements to be provided.

Modelling of solutions

Making the equipment and preparations adapted to your needs.

Tests with quality control

Performing preliminary or preseries tests.

Maintenance

On-site or remote intervention.

Training

We ensure the training of your teams for a perfect control of the processes and equipment. LAM PLAN is approved by a professional training agency.

We have developed over the years a strong culture in Consulting and Services to allow you to attain your objectives.

Our design & engineering department intervenes especially to help you:

- Obtain the surface condition and/or inherent flatness desired

- Gain in productivity

- Control lapping and polishing processes

Thanks to our experience with problematics linked to polishing technologies, we can transfer our know-how to make all the players concerned by these topics advance. Whether our own teams or those of our customers are involved, we permanently train any person wishing to become more competent to guarantee a first class industrial performance.

Our technicians are at your disposal to assist you in the usage of the products and consumables and the implementation and maintenance of the processes and equipment.

Availability & responsiveness

Under any circumstance, at any time and anywhere, our teams will know how to respond to your needs and expectations..

Training

Super finish lapping training

Super finish lapping training for the maintenance of tightness parts:

-

Length

1 day

-

Who should attend

Maintenance department managers, foremen and operating personnel having an activity centred around the repair of mechanical elements including tightness parts : mechanical seals, pumps, safety valves, valves, fittings, etc.

-

Objectives

Redefine the concept of lapping and super finish.

Introduction to the basic flat lapping techniques on machines and manually. -

Participants

In our premises : 5 persons. Maximum

In your premises : 10 persons. Maximum -

Program

Theoretical course

FLAT LAPPING

- Definition

- Surface condition – inherent flatness standards

- Principle, support / free abrasive

- Classic lapping

- Applications – results

- LAM PLAN super finish lapping

- Applications – results

- Polishing

FLAT LAPPING MACHINES

- Kinematics

- Plate’s inherent flatness

MANUAL LAPPING EQUIPMENT and PRODUCTS

- Usage

- Servicing

CONTROL

- Inherent flatness

- Surface condition

GEOMETRIC LAPPING

- Equipment

- Usage

Hands-on course in the workshop

FLAT LAPPING MACHINES

- Correction of the plate’s inherent flatness

- Abrasive distribution

- Placement of the parts

- Testing

MANUAL LAPPING BLOCKS

- Manipulation

GEOMETRIC LAPPING MACHINES

- Manipulation

MONOCHROMATIC LAMP

- Presentation

- Usage

-

Equipment

Manual lapping equipment may be made available to the participants.

-

Registration

Submit the contact form or call +33 (0)4 50 43 96 30

Metallographic training

Training for the preparation of metallographic samples:

-

Length

1 day

-

Who should attend

Laboratory heads and preparers having an activity concerning the preparation of metallographic samples in view of an examination with an optical microscope or scanning electron microscope (SEM).

-

Objectives

Introduction to LAM PLAN preparation techniques:

Cutting – Embedding – Prepolishing – Polishing -

Participants

3 persons maximum in our premises.

-

Program

The training consists of two courses : A theoretical course during which all the steps in the preparation process will be studied. A hands-on course will then indicate how to handle the various significant materials.

EXAMINATION

- Definition of the examination

- Examination of the structure

- Counting the inclusions

- Examination of the layer

CLASSIFICATION OF MATERIALS

- Concept of hardness

- Homogeneous materials

- Composite materials

- Sandwich materials

CUTTING

- Choice of the cut-off wheel

- Defects due to bad cutting off

EMBEDDING

- Choice of the resin according to material

- Sample holder

PREPOLISHING

- CAMEO® techniques

POLISHING

- CAMEO® techniques

-

Equipment

All the equipment required for the hands-on work will be made available to the participants who may bring their own samples.

-

Registration

Submit the contact form or call +33 (0)4 50 43 96 30