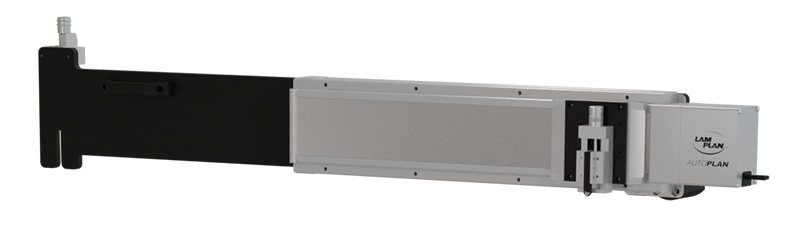

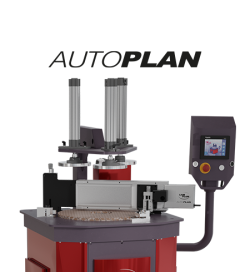

AUTOPLAN system

The AUTOPLAN system enables efficient management of the flatness and grooving of the LAM PLAN lapping & polishing machines.

Dedicated to machines 9000 series

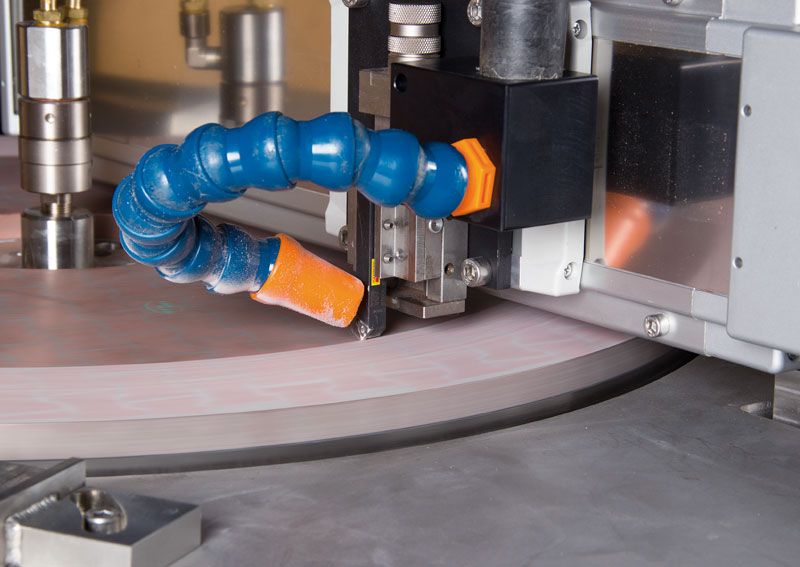

The AUTOPLAN system enables efficient plate flatness and grooving in order to create structures which modifier it’s properties. The principle lies in plate machining with a moving cutting tool. The AUTOPLAN is positioned and mounted in a few minutes thanks to the dedicated fixation points integrated in our machines.

At present, the automatic AUTOPLAN system can be integrated in LAM PLAN machines up to model M.M.9150. It is installed on dedicated points on the machine structure. Driven directly by the control interface, you can manage forward speed in order to carry out flattening or grooving operations. The AUTOPLAN produces spiral grooving. This system is faster and more precise than the DIABLOC. It is also easier to manage and to reproduce the required support geometry (flat, concave or convex).

Production stoppage for plate reconditioning is reduced and productivity is increased.

AUTOPLAN for lapping machine M.M.9480

| Lapping machine |

Model | Ref. |

| AUTOPLAN for M.M.9480 with SUPPORT TROLLEY | E version | 10 9480AP 00 |

| S version |

AUTOPLAN for lapping machine M.M.9700

| Lapping machine |

Model | Ref. |

| AUTOPLAN for M.M.9700 with SUPPORT TROLLEY | E version | 10 9700AP 00 |

| S version | ||

| S HP version |

AUTOPLAN for lapping machine M.M.9100

| Lapping machine |

Model | Ref. |

| AUTOPLAN for M.M.9100 with SUPPORT TROLLEY | E version | 10 9100AP 00 |

| S version | ||

| SR version | ||

| EC version |

AUTOPLAN for lapping machine M.M.9120

| Lapping machine |

Model | Ref. |

| AUTOPLAN for M.M.9120 | E version | 10 9120AP 00 |

| S version | ||

| SR version | ||

| S4 version | ||

| SR4 version |

AUTOPLAN for lapping machine M.M.9150

| Lapping machine |

Model | Ref. |

| AUTOPLAN for M.M.9150 | E version | 10 9150AP 00 |

| S version |