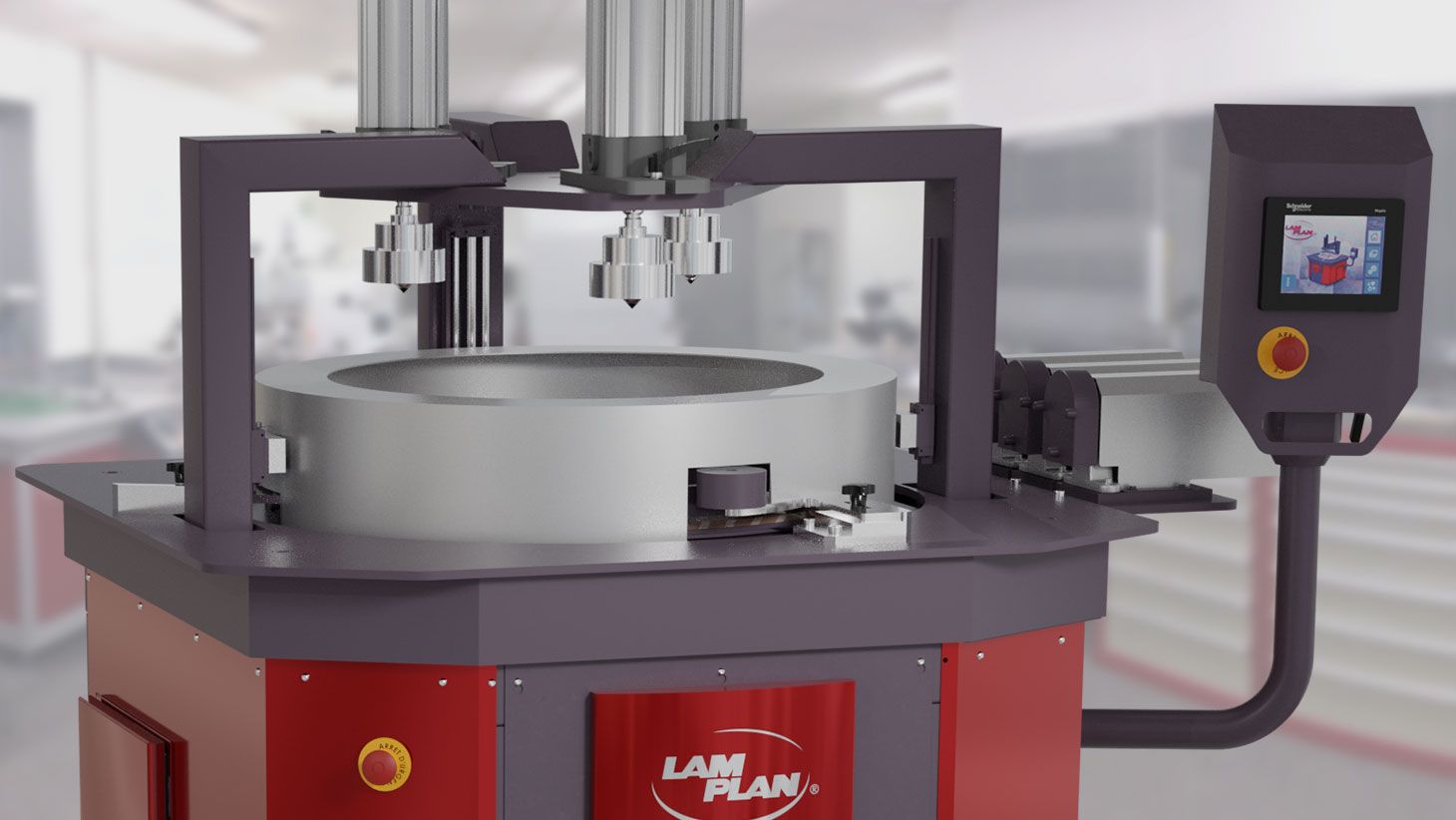

Lapping & polishing machine for intensive production for parts: Ø 5 to 210 mm

M.M.9700 E version

M.M.9700 S version

M.M.9700 S HP version

-

Plate Ø700 mm

-

Plate rotation speedFrom 30 to 90 rpm

-

Inner ring Ø274 mm

-

Weight (without plate)800 kg

M.M.9700

E version, S version and S HP version (high power)

Fitted with a Ø 700 mm lapping plate, this machine has a new, highly intuitive touchscreen, enabling the user to quickly grasp the operation of the machine.

From a mechanical viewpoint, a large dimension thrust ball bearing is inserted under the machine’s basic plate. This mechanism guarantees plate stability, even under a heavy load.

This new concept also enables reduced demand on the gear motor group, assuring greater longevity of the equipment. Machine safety has also been improved with anti-pinch devices connected to the retaining arm castors of the conditioning rings.

Finally, the machine’s new electrical design, allows easy development of machine functions and will respond to the evolution of your needs, with, for example, later integration of the AUTOPLAN system, or different types of LAM PLAN distribution systems.

Therefore, this machine is intended for use in all high production workshops.

Design

and advanced technology

The safety has also been improved in this machine with an anti-pinch function attached to the casters of the arms maintaining the conditioning rings.

Technical characteristics

and equipment

All M.M.9000 series machines are fitted with an integrated modem as standard in order to carry out remote maintenance operations. They are compatible with dedicated LAM PLAN distribution systems and can be optionally fitted with an abrasive and lubricant level sensor. Production data collection in the form of CSV files is possible via the USB interface.

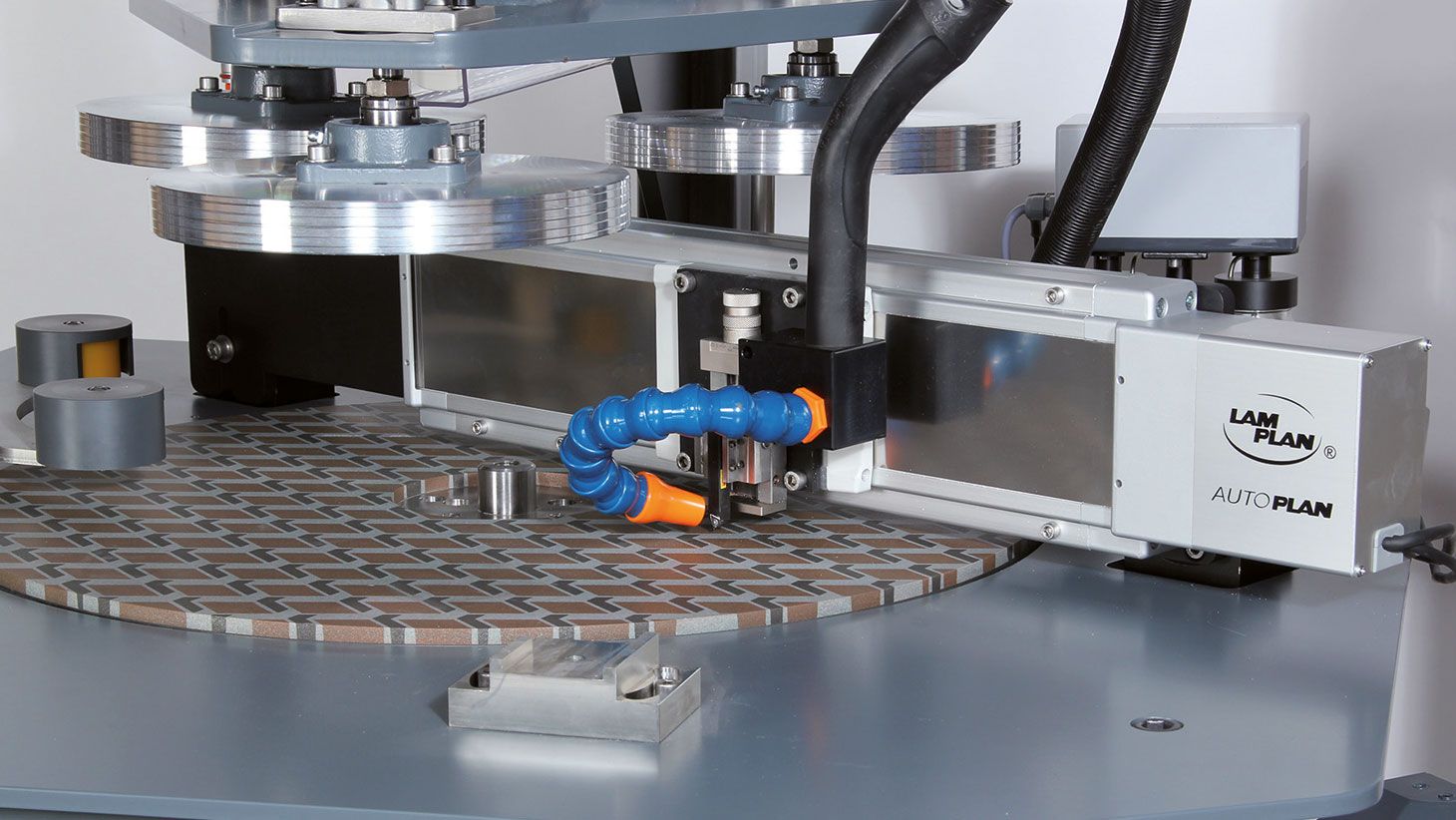

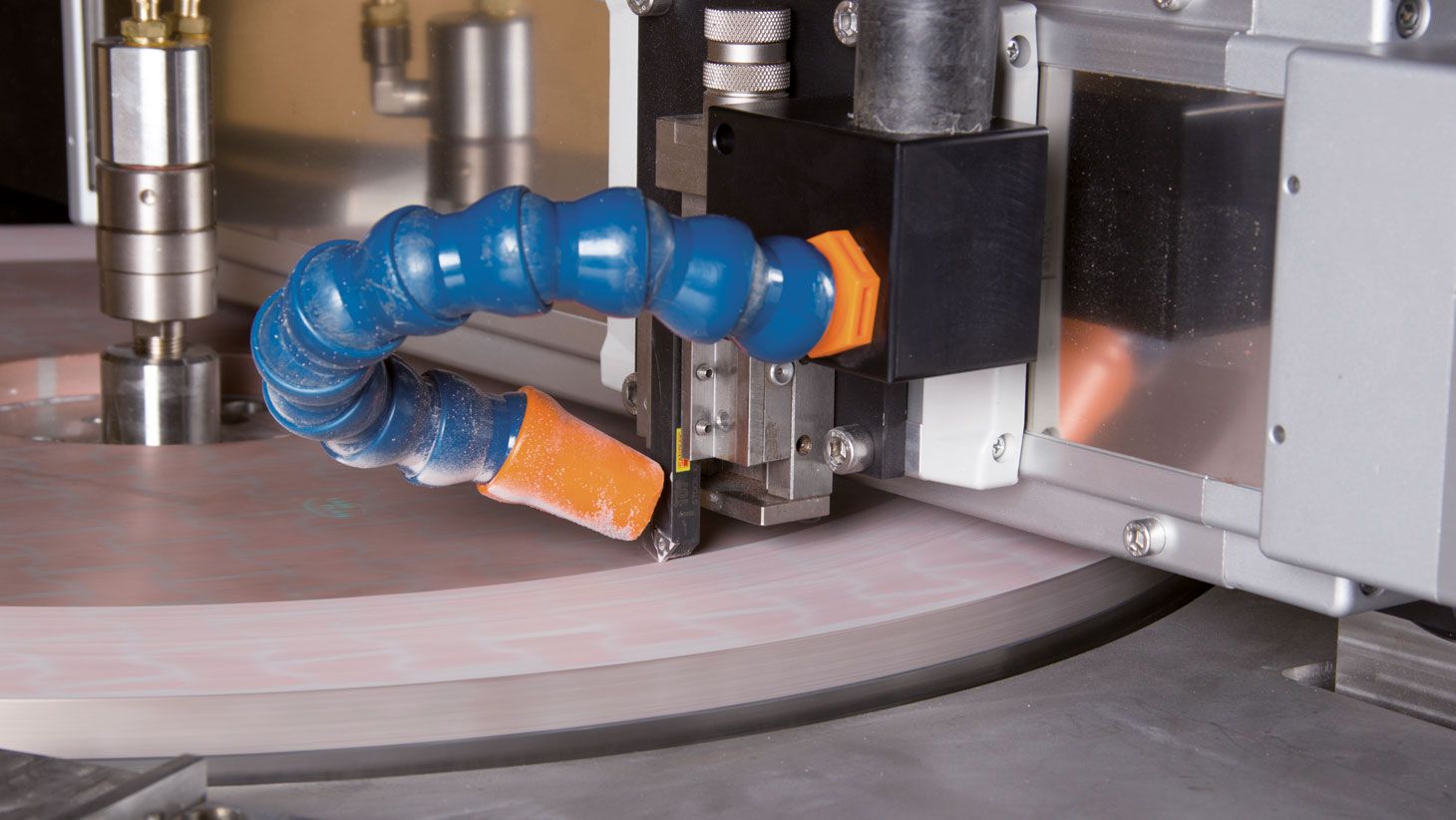

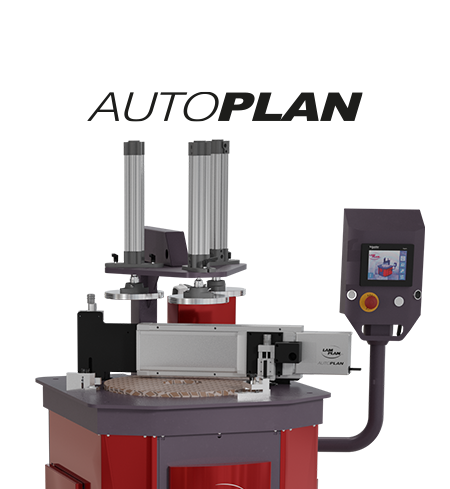

Option LAM PLAN AUTOPLAN

AUTOPLAN system enables to manage efficiently the flatness and the grooving of the plate. It is installable and removable in a few minutes thanks to fixation points integrated to the machine.

Downloads

Technical data M.M.9700 E version

Plate Ø | 700 mm |

Inner ring Ø | 274 mm |

Capacity per ring | 1 part Ø 210 mm or 160 parts Ø 10 mm |

Number of rings | 3 |

Electric power supply | 400 V – 50 Hz – 3 phases + earth + neutral |

Motor Power | 2.2 kW |

Pressure application system | 3 weights of 13 kg included |

Control | Touch screen 5,7 inches |

Plate rotation speed | From 30 to 90 rpm |

Dim. (W x H x D) | 1500 x 1300 x 1450 mm |

Weight (without plate) | 800 kg |

Abrasive distribution system | Included Type depending on the plate |

Reference | 10 9700E 00 |

Options for M.M.9700 E

-

Level sensors for diamond liquid and lubricating fluid08 90001 00

-

Flatness gauge for checking the flatness of the lapping plate08 00894 00

Technical data M.M.9700 S version

The M.M.9700 S version of the machine integrates a pneumatic pressure system which is controlled from the general interface.

Comprising three double effect cylinders and three ball mounted aluminium discs, this device negates handling weights.

Loading and unloading times are optimised and handling effort is reduced.

Pressure can be adjusted between 0 and 700 N.

What changes from E version

Pressure application system | 3 double effect cylinders |

Pressure | Between 0 and 700 N |

Dim. (W x H x D) | 1500 x 1500 x 1900 mm |

Weight (without plate) | 1000 kg |

Reference | 10 9700S 00 |

Options for M.M.9700 S

-

Level sensors for diamond liquid and lubricating fluid08 90001 00

-

Refrigeration and heating unit P803, for lapping plate10 80003 90

-

Flatness gauge for checking the flatness of the lapping plate08 00894 00

Technical data M.M.9700 S HP version

A machine specially developed to answer polishing needs in production of parts requiring high pressure, associated with high speed plate rotation and use of specific abrasives.

The pressure system and motorisation have been adapted to the specific requirements of heavy loads and high torque.

The use of stainless steel in the machine’s production, is generalised to resist certain relatively aggressive abrasive types. The machine is equipped with protective casing around the work zone, to avoid high speed projection of abrasives. It is removable and motorised.

The M.M.9700 S HP can be fitted with distribution systems suited to the required abrasives, for example high flow peristaltic pumps.

What changes from E version

Motor Power | 7.5 kW |

Pressure application system | 3 double effect cylinders |

Pressure | 100 to 2500 N |

Plate rotation speed | From 15 to 125 tr/mn |

Dim. (W x H x D) | 1540 x 1200 x 1800 mm |

Weight (without plate) | 980 kg |

Reference | 10 9700SP 00 |

Options for M.M.9700 S HP

-

Refrigeration and heating unit P803, for lapping plate10 80003 90

-

Flatness gauge for checking the flatness of the lapping plate08 00894 00

Available accessories

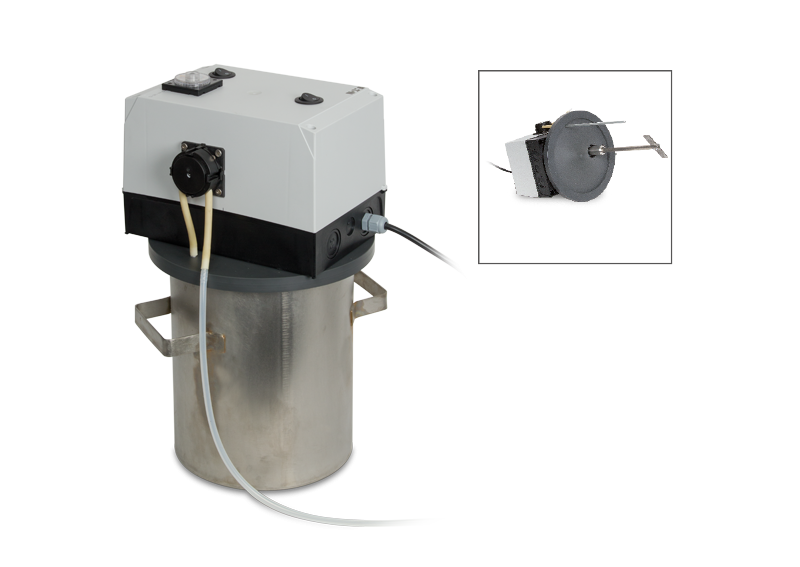

Dosing unit type 709

Peristaltic model dedicated to LAM PLAN machines.

- Capacity: 2 x 500 cc including 1 with agitator

- Electric power supply: 220V single phase + 24 V input for control

- Pump flow rate: 0,5 ml/sec.

- Distribution system: nozzles not included

Dosing unit type 710

Peristaltic model dedicated to LAM PLAN machines, recommended for oil-based products.

- Capacity: 2 x 500 cc including 1 with agitator

- Electric power supply: 220V single phase + 24 V input for control

- Pump flow rate: 0,5 ml/sec.

- Distribution system: nozzles not included

Dosing unit type 719

Peristaltic model dedicated to LAM PLAN machines, recommended for oil-based products.

- Capacity: 2 x 500 cc including 1 with agitator

- Electric power supply: 220V single phase + 24 V input for control

- Pump flow rate: N.C.

- Distribution system: nozzles not included

Dosing pump type 8017

Controlled by the machine interface or by integrated sequencer for the autonomous version.

- Pump type: 1 peristaltic pump + mixing system

- Bowl: useful volume 7 litres

- Electrical power supply: 220V single-phase

- Pump flow rate: 3,5 ml/sec.

- Distribution system: nozzle 813 on mobile stand supplied with the dosing unit

| Designation |

Qty. | Capacity | Ref. |

| Dosing pump type 8017 for LAM PLAN machine | 1 | 7 litres | 08 08017 00 |

| Indepedent dosing pump type 8017 | 1 | 7 litres | 08 18017 00 |

Dosing pump type 8003

Controlled by the machine interface or by integrated sequencer for the autonomous version.

- Pump type: 1 vortex pump + mixing system

- Bowl: useful volume of 50 litres, on casters, drain valve

- Electrical power supply: 220V single-phase

- Pump flow rate: 50 litres/minute

- Distribution system: 3 swivelling outputs. Solenoid valve 3 tracks controlled by the sequencer included with the pump.

| Designation |

Qty. | Capacity | Ref. |

| Dosing pump type 8003 for LAM PLAN machine | 1 | 50 litres | W000 08003 |

| Indepedent dosing pump type 8003 | 1 | 50 litres | W001 08003 |

Dosing pump type 8007

Controlled by the machine interface or by integrated sequencer for the autonomous version.

- Pump type: 1 vortex pump

- Bowl: useful volume 7 litres

- Electrical power supply: 220V single-phase

- Pump flow rate: 25 litres/minutes

- Distribution system: 3 swivelling outputs. Solenoid valve 3 tracks controlled by the sequencer included with the pump.

| Designation |

Qty. | Capacity | Ref. |

| Dosing pump type 8007 for LAM PLAN machine | 1 | 7 litres | W000 08007 |

| Indepedent dosing pump type 8007 | 1 | 7 litres | W001 08007 |

Autonomous dosing unit M.M.809B – Venturi

- Distribution system:

– Distribution of 2 different liquids by Venturi system

– 1 liquid compartment with an agitator - Control: By analog buttons and timers

- Compressed air feed system: 2 bars

- Electrical power supply: 220 V single-phase- 50 Hz

- Dosing machine communication: 1 x 220 V input for machine servoing

| Designation |

Qty. | Dim. | Ref. |

| Dosing unit M.M.809B | 1 | with 2 glass bottles 500 cc | 08 01809 10 |

Autonomous dosing unit M.M.909 – Peristaltic

- Distribution system: 3 standard peristaltic pumps with an outlet to drive an external pump

- Control: touch screen

- Electrical power supply: 220 V single-phase – 50 Hz

- Dosing machine communication: 1 x 24 V input for machine servoing

| Designation |

Qty. | Dim. | Ref. |

| Dosing unit M.M.909 ADAPTABLE VERSION With a manual start/stop button |

1 | with 3 glass bottles 500 cc | 08 03799 00 |

| Stirrer | 1 | for glass bottle 500 cc | 08 02816 00 |

Autonomous dosing unit M.M.909 HV – Peristaltic

- Distribution system: 2 standard peristaltic pumps, 1 large flow pump for high viscosity liquids and an outlet to drive an external pump

- Control: touch screen

- Electrical power supply: 220 V single-phase – 50 Hz

- Dosing machine communication: 1 x 24 V input for machine servoing

| Designation |

Qty. | Dim. | Ref. |

| Dosing unit M.M.909 HV | 1 | with 3 glass bottles 500 cc | 08 00799100 |

| Stirrer | 1 | for glass bottle 500 cc | 08 02816 00 |

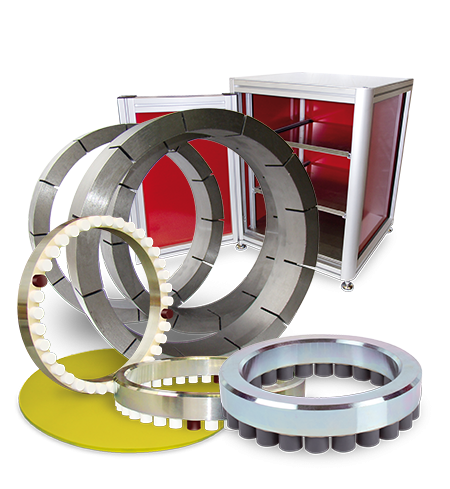

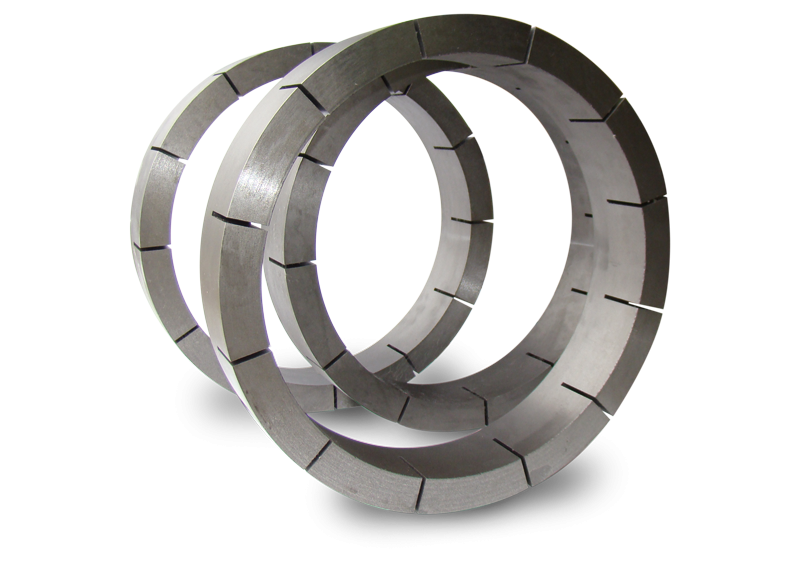

Cast iron conditioning rings (Ø 700 mm)

We carefully select special high quality cast iron for optimum, durable results. Suitable for all lapping machines, whatever the brand or size.

Available from stock or produced to order.

| Ø | Ø in mm | Qty. | Ref. | |

| Ext. | Int. | |||

| 27″ | 315 | 275 | 1 | U315 A0711 |

| 36″ | 419 | 368 | 1 | U419 A0914 |

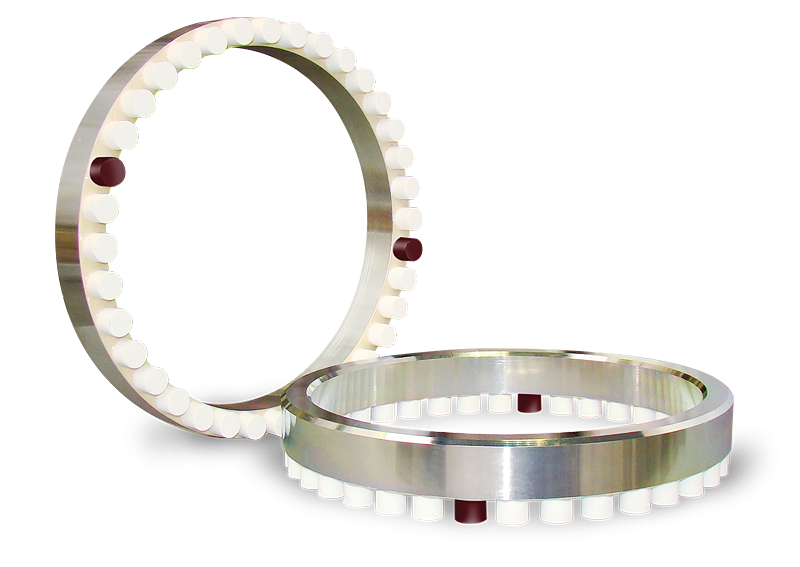

Ceramic conditioning rings with SPYLAP® 27″ (Ø 700 mm)

Prevent mechanical distortion problems. The ceramic rings enable you to preserve the flatness of the plate, to manage its heating, as well as limiting contamination thanks to the absence of graphite.

The SPYLAP® sensor enables the user to visually prevent a significant mechanical distortion of the lapping (or polishing) support and of the part to be lapped. The SPYLAP® permanently monitors the temperature of the support and changes from black to red at a precisely predefined temperature.

| Ø in mm | Qty. | Ref. | |

| Ext. | Int. | ||

| 317 | 275 | 1 | 08 87562 10 |

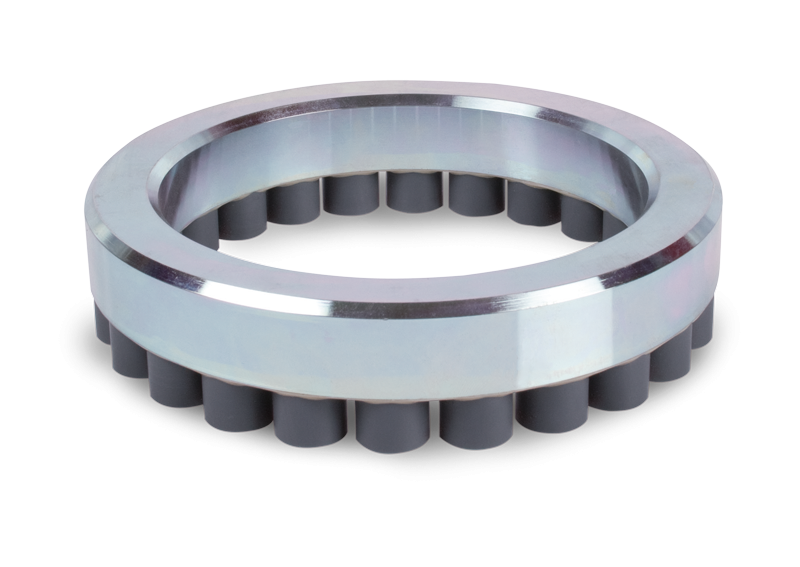

Plastic rings 27″ (Ø 700 mm)

| Ø in mm | Qty. | Ref. | |

| Ext. | Int. | ||

| 317 | 275 | 1 | 08 87512 00 |