Manual lapping rods

Lapping rods M.M.®, shapes As A, B, C et Lapidaries

Lapping rods M.M.®

Immediately shape your rods in all form, from patented M.M.® preliminary shape containing no abrasive.

Applications

Applications

For internal and external lapping, and super finishing of spherical, conical and cylindrical parts and many other shapes.

The solution

LAM PLAN offers an original, functional and adapted solution; it responds to the requirements of surface conditions difficult to attain with tools or grinding wheels. LAM PLAN delivers its rods in preliminary shape condition. The user finalises the form of his choice.

A fast machining using common tools (never a grinding wheel) allows adapting the rods to the shapes of the parts to be lapped and then proceeding with the lapping- polishing ion machines or manually in some cases. This technique is possible thanks to the LAM PLAN M.M.® which combines rods and free diamond abrasives.

The technique

The LAM PLAN M.M.® rods consists of two different materials in terms of mechanical, physical and resistance characteristics. The composition and arrangement of the two components associated with the usage of specific diamond abrasive is the base of the patented LAM PLAN M.M® system and its effectiveness.

The advantages of the LAM PLAN M.M.® system associated with Bio DIAMANT®

The LAM PLAN M.M.® system uses special abrasives. A chemical binder allows homogeneous, stable distribution of calibrated diamond grains, while preventing any settling phenomenon. As soon as the rod starts rotating under the effect of the applied pressure and the passage on the two different materials, the diamond grains move and fix alternatively. This causes a phenomenon of significant acceleration of these particles ensuring a high stock removal. Penetrating very low and for a very short time in the rod’s metal mass, each diamond particle always presents an edge opposite to the part to be machined.

All the cutting edges work under an over speed. The abrasive’s efficiency is therefore better and more sustainable.

In addition, thanks to the use of diamond, the rod coating does practically not wear out (good behaviour in terms of shape or inherent flatness).

The LAM PLAN type M.M.® lubricant vaporised in a very small quantity allows cleaning the diamond’s cutting edges loaded with metal waste and operates cooling action.

The small quantity of lubricant significantly reduces the “machining sludge” volume. The work is cleaner and produces less waste.

Qualities

In order to obtain surface conditions varying from 0.2 to 0.01 micron/Ra, LAM PLAN proposes various types of rods. The distribution of the 2 materials which make up the patented bi-component rods type M.M.® remains constant, regardless of the shape given to them. The rods type 2000 are mono-components. They benefit from the quality of bi-component materials, but their efficiency is lower and their wear more rapid.

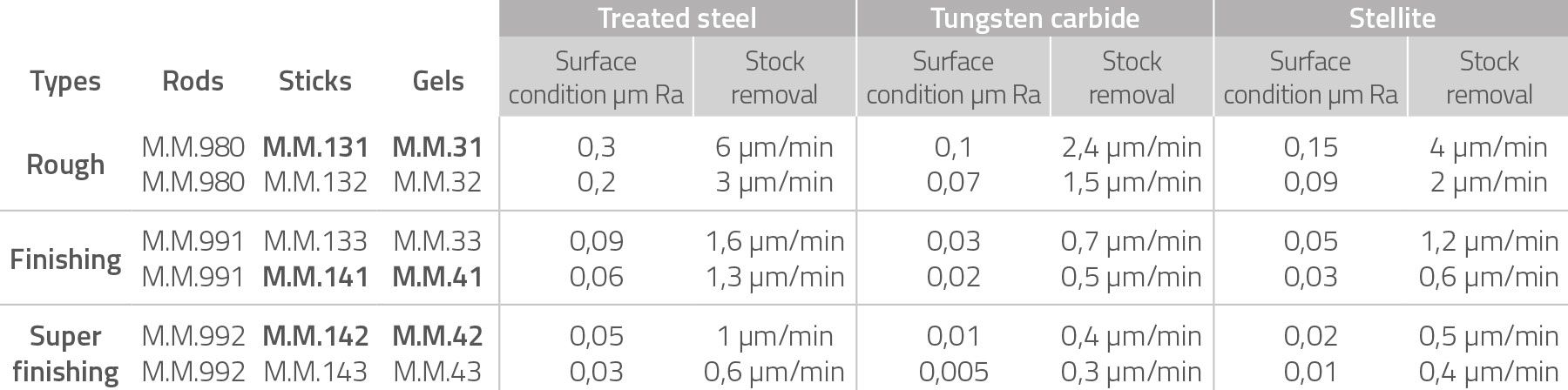

| Types |

|

| Patented M.M. Rods Bi-components |

M.M.® 980 lapping |

| M.M.® 991 finishing | |

| M.M.® 992 superfinishing | |

| Economic range Mono-component |

2002 lapping |

| 2003 polishing |

Rods M.M.® shape A

Cylindrical preliminary shape intended to be machined by turning with a dry carbide tool in order to adapt to the parts to be treated.

| Implementation example |

||||

Lapped part |

Material |

Rod |

Abrasive |

Result |

| Cupule for thigh prosthesis | Chromium cobalt | Shape A Type 992 |

Stick M.M. 143 |

Sphericity 3 µm |

| Type |

Ø in mm | Ref. |

| 991 | 25 x 100 | 09 09991 28 |

| 992 | 25 x 100 | 09 09992 28 |

| 2002 | 25 x 100 | 09 20022 20 |

| 2003 | 25 x 100 | 09 20032 20 |

| 980 | 50 x 50 | 09 09980 10 |

| 991 | 50 x 50 | 09 09991 10 |

| 992 | 50 x 50 | 09 09992 10 |

| 2002 | 50 x 50 | 09 20021 10 |

| 2003 | 50 x 50 | 09 20031 10 |

| 2002 | 50 x 100 | 09 20022 10 |

| 2003 | 50 x 100 | 09 20032 10 |

| 2002 | 50 x 150 | 09 20023 10 |

| 2003 | 50 x 150 | 09 20033 10 |

| 980 | 75 x 50 | 09 09980 80 |

| 991 | 75 x 50 | 09 09991 80 |

| 992 | 75 x 50 | 09 09992 80 |

| 2002 | 75 x 50 | 09 20021 80 |

| 2003 | 75 x 50 | 09 20031 80 |

| 2002 | 75 x 100 | 09 20022 80 |

| 2003 | 75 x 100 | 09 20032 80 |

| 2002 | 75 x 150 | 09 20023 80 |

| 2003 | 75 x 150 | 09 20033 80 |

| 2002 | 100 x 50 | 09 20021 90 |

| 2003 | 100 x 50 | 09 20031 90 |

| 2002 | 100 x 100 | 09 20022 90 |

| 2003 | 100 x 100 | 09 20032 90 |

| 2002 | 100 x 150 | 09 20023 90 |

| 2003 | 100 x 150 | 09 20033 90 |

Custom machining package

Custom machining package

| Designation |

Qty. | Ref. |

| Custom machining package | 1 | 99 SAV0F 00 |

Rods M.M.® shape B

Our Shape B rods are composed of a 5 mm active part fixed to a steel* ensuring great rigidity. Please contact us for dimensions above 200 mm. To machine the rods and use them, the shapes A or B must be tightened in a mandrel one turn mounted on a metal rod (by tapping or gluing).

NOT: The tapping must always remain below the steel* thickness in the case of shapes B.

In any case (shapes A or B), the centre of the coating has to be cleared to avoid the dead point. During shaping, it is recommended to recover the chips and dusts to reduce the cleaning time.

*aluminium base on demand

| Implementation example |

||||

Lapped part |

Material |

Rod |

Abrasive |

Result |

| Safety valve | Satellite | Shape B Type 991 |

Stick M.M.141 |

Tightness |

| Type |

Ø in mm | Ref. |

| 980 | 50 x 15 | 09 09980 30 |

| 991 | 50 x 15 | 09 09991 30 |

| 992 | 50 x 15 | 09 09992 30 |

| 2002 | 50 x 15 | 09 02002 30 |

| 2003 | 50 x 15 | 09 02003 30 |

| 980 | 100 x 15 | 09 09980 40 |

| 991 | 100 x 15 | 09 09991 40 |

| 992 | 100 x 15 | 09 09992 40 |

| 2002 | 100 x 15 | 09 02002 40 |

| 2003 | 100 x 15 | 09 02003 40 |

| 980 | 150 x 15 | 09 09980 50 |

| 991 | 150 x 15 | 09 09991 50 |

| 992 | 150 x 15 | 09 09992 50 |

| 2002 | 150 x 15 | 09 02002 50 |

| 2003 | 150 x 15 | 09 02003 50 |

| 980 | 200 x 15 | 09 09980 60 |

| 991 | 200 x 15 | 09 09991 60 |

| 992 | 200 x 15 | 09 09992 60 |

| 2002 | 200 x 15 | 09 02002 60 |

| 2003 | 200 x 15 | 09 02003 60 |

Custom machining package

Custom machining package

| Designation |

Qty. | Ref. |

| Custom machining package | 1 | 99 SAV0F 00 |

Lapidary M.M.® shape C

Intended to prepare the rods for the machine of special shaped parts.

| Implementation example |

||||

Lapped part |

Material |

Rod |

Abrasive |

Result |

| Rolling machine cylinder | Fonte | Shape C Type 980 |

Stick M.M.133 |

Roughness Ra 0,08 |

| 3 units | ||

| Types |

Dim. (mm) | Ref. |

| 980 | 10 x 20 x 560 | 09 08445 30 |

| 991 | 10 x 20 x 560 | 09 08446 30 |

| 992 | 10 x 20 x 560 | 09 08449 30 |

Custom machining package

Custom machining package

| Designation |

Qty. | Ref. |

| Custom machining package | 1 | 99 SAV0F 00 |

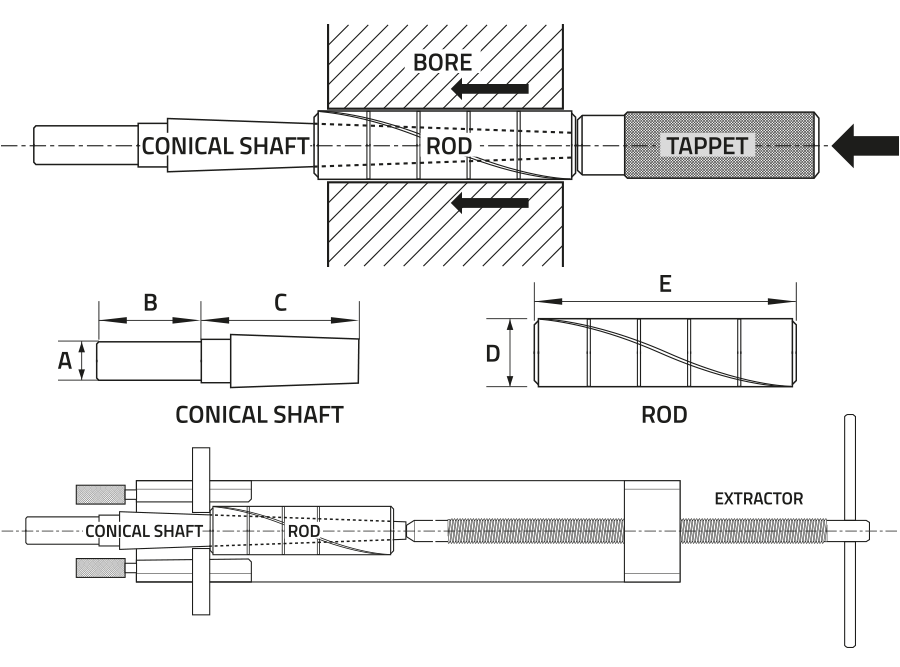

Expandable cylindric rods

The formula for the accuracy of borings.

The set is composed of:

- A conical shaft to be mounted on the mandrel.

- A cast iron rod with pinched structure. A helical slot allows the expansion while maintaining its geometric shape. The rod’s interior is conical in order to receive the shaft.

- A tube-shaped pushrod is here allows driving the rod on the shaft.

Procedure

The abrasives to be used with the rods is selected according to their tasks:

- Important stock removal: diamond dosing stick M.M.132

- Super-finishing : diamond dosing stick M.M.142 or 144

Lubrication thanks to the M.M.712 fluid.

Use

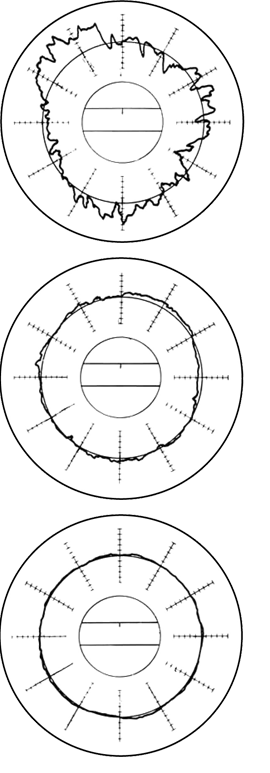

Results

A 15,9 mm diameter has been drilled on a 38 mm length.

After checking, an ovalisation of 4/100th mm has been revelled and a surface condition of 0.5-micron Ra.

First operation

With rod and diamond

dosing stick M.M.132: ovalisation reduced to 4/10th micron. surface condition of 0.12-micron Ra..

Second operation

With rod and diamond dosing stick M.M.144: limited ovalisation to 1/10th micron. Surface condition to 0.03-

micron Ra.

Expandable cylindric rods

| Ø (mm) |

Lenght E (mm) | Expansion D (mm) | Ref. |

| 1,19 | 12,70 | 1,168 à 1,397 | 99 91011 90 |

| 1,59 | 15,85 | 1,574 à 1,930 | 99 91015 90 |

| 1,98 | 15,85 | 1,956 à 2,311 | 99 91019 80 |

| 2,38 | 19,05 | 2,362 à 2,743 | 99 91023 80 |

| 2,78 | 19,05 | 2,743 à 3,099 | 99 91027 80 |

| 3,17 | 22,19 | 3,149 à 3,479 | 99 91031 70 |

| 3,57 | 22,19 | 3,530 à 3,886 | 99 91035 70 |

| 3,97 | 22,19 | 3,937 à 4,318 | 99 91039 70 |

| 4,37 | 22,19 | 4,318 à 4,673 | 99 91043 70 |

| 4,76 | 34,91 | 4,724 à 5,105 | 99 91047 60 |

| 5,16 | 34,91 | 5,130 à 5,461 | 99 91051 60 |

| 5,56 | 44,45 | 5,537 à 5,918 | 99 91055 60 |

| 5,95 | 44,45 | 5,918 à 6,248 | 99 91059 50 |

| 6,35 | 50,80 | 6,324 à 6,705 | 99 91063 50 |

| 6,75 | 50,80 | 6,731 à 7,010 | 99 91067 50 |

| 7,14 | 50,80 | 7,112 à 7,340 | 99 91071 40 |

| 7,54 | 50,80 | 7,518 à 7,670 | 99 91075 40 |

| 7,94 | 50,80 | 7,924 à 8,305 | 99 91079 40 |

| 8,33 | 50,80 | 8,305 à 8,610 | 99 91083 30 |

| 8,73 | 50,80 | 8,712 à 8,915 | 99 91087 30 |

| 9,13 | 50,80 | 9,093 à 9,245 | 99 91091 30 |

| 9,53 | 63,50 | 9,499 à 9,855 | 99 91095 30 |

| 9,92 | 63,50 | 9,906 à 10,185 | 99 91099 20 |

| 10,32 | 63,50 | 10,287 à 10,515 | 99 91103 20 |

| 10,72 | 63,50 | 10,693 à 10,845 | 99 91107 20 |

| 11,11 | 63,50 | 11,074 à 11,430 | 99 91111 10 |

| 11,51 | 63,50 | 11,480 à 11,785 | 99 91115 10 |

| 11,91 | 63,50 | 11,861 à 12,090 | 99 91119 10 |

| 12,30 | 63,50 | 12,268 à 12,420 | 99 91123 00 |

| 12,70 | 82,55 | 12,674 à 13,081 | 99 91127 00 |

| 13,49 | 82,55 | 13,462 à 13,868 | 99 91134 90 |

| 14,29 | 82,55 | 14,249 à 14,579 | 99 91142 90 |

| 15,08 | 82,55 | 15,062 à 15,290 | 99 91150 80 |

| 15,88 | 82,55 | 15,849 à 16,256 | 99 91158 80 |

| 16,67 | 82,55 | 16,637 à 16,941 | 99 91166 70 |

| 17,46 | 82,55 | 17,424 à 17,627 | 99 91174 60 |

| 18,26 | 82,55 | 18,237 à 18,415 | 99 91182 60 |

| 19,05 | 88,90 | 19,024 à 19,380 | 99 91190 50 |

| 19,84 | 88,90 | 19,812 à 20,116 | 99 91198 40 |

| 20,64 | 88,90 | 20,599 à 20,853 | 99 91206 40 |

| 21,43 | 88,90 | 21,412 à 21,615 | 99 91214 30 |

| 22,23 | 88,90 | 22,199 à 22,580 | 99 91222 30 |

| 23,02 | 88,90 | 22,987 à 23,342 | 99 91230 20 |

| 23,81 | 88,90 | 23,774 à 24,079 | 99 91238 10 |

| 24,61 | 88,90 | 24,587 à 24,790 | 99 91246 10 |

Conical shafts

| N° |

Ø A (mm) |

Lenght B (mm) | Lenght C (mm) | Ref. |

| 4/0 | 3,17 | 19,05 | 39,10 | 99 92004 00 |

| 3/0 | 3,17 | 19,05 | 39,10 | 99 92003 00 |

| 2/0 | 3,17 | 19,05 | 41,25 | 99 92002 00 |

| 0 | 3,17 | 19,05 | 44,45 | 99 92000 00 |

| 1 | 4,74 | 25,40 | 69,85 | 99 92000 10 |

| 2 | 4,76 | 25,40 | 76,20 | 99 92000 20 |

| 3 | 4,76 | 25,40 | 101,60 | 99 92000 30 |

| 4 | 5,53 | 25,40 | 101,60 | 99 92000 40 |

| 5 | 9,79 | 38,10 | 127,00 | 99 92000 50 |

| 6 | 7,90 | 38,10 | 127,00 | 99 92000 60 |

| 7 | 9,51 | 38,10 | 152,40 | 99 92000 70 |

| 8 | 10,27 | 38,10 | 152,40 | 99 92000 80 |

| 9 | 12,70 | 50,80 | 177,80 | 99 92000 90 |

| 10 | 12,70 | 50,80 | 177,80 | 99 92001 00 |

Tappets

| N° |

Ref. |

| 4/0 | 99 93004 00 |

| 3/0 | 99 93003 00 |

| 2/0 | 99 93002 00 |

| 0 | 99 93000 00 |

| 1 | 99 93000 10 |

| 2 | 99 93000 20 |

| 3 | 99 93000 30 |

| 4 | 99 93000 40 |

| 5 | 99 93000 50 |

| 6 | 99 93000 60 |

| 7 | 99 93000 70 |

| 8 | 99 93000 80 |

| 9 | 99 93000 90 |

| 10 | 99 93001 00 |

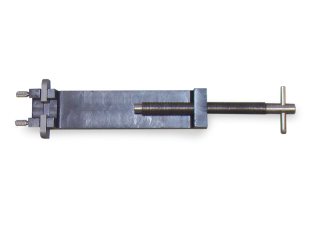

Extractors

| Characteristics |

Réf. |

| For rods Ø 1,19 à 4,37 mm | 99 94000 10 |

| For rods Ø 4,76 à 15,48 mm | 99 94000 20 |

| For rods Ø 15,88 à 31,75 mm | 99 94000 30 |

Any other dimension, on demand.

Guidance

Example of implementation