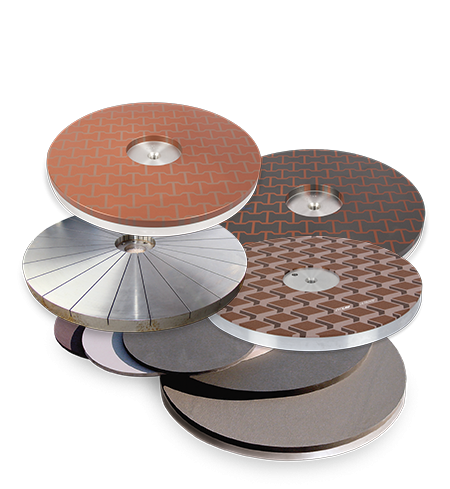

Abrasive films

High concentration abrasive films: diamond, & alumina.

Alumina abrasive films

High concentration abrasive films. Available in different grains from 0.3 µm to 40 µm, they generate excellent flatness and finishing results. The uniformity of the abrasive layer ensures exceptional regularity of the polishing process and prolonged durability of the disc.

Easy to use, high stock removal and polishing quality enables you to significantly reduce your sample polishing time. They can be used with all material types.

Recommended lubricants: FLUIDE 712 water-based or FLUIDE 705 oil-based.

| 100 pieces | Self-adhesive |

|

| Ø in mm |

µm | Ref. |

| 200 | 0,3 | 05A 98A0 200C |

| 200 | 0,5 | 05A 95A0 200C |

| 200 | 1 | 05A 01A0 200C |

| 200 | 2 | 05A 02A0 200C |

| 200 | 3 | 05A 03A0 200C |

| 200 | 5 | 05A 05A0 200C |

| 200 | 9 | 05A 09A0 200C |

| 200 | 12 | 05A 12A0 200C |

| 200 | 15 | 05A 15A0 200C |

| 200 | 30 | 05A 30A0 200C |

| 200 | 40 | 05A 40A0 200C |

| 250 | 0,3 | 05A 98A0 250C |

| 250 | 0,5 | 05A 95A0 250C |

| 250 | 1 | 05A 01A0 250C |

| 250 | 2 | 05A 02A0 250C |

| 250 | 3 | 05A 03A0 250C |

| 250 | 5 | 05A 05A0 250C |

| 250 | 9 | 05A 09A0 250C |

| 250 | 12 | 05A 12A0 250C |

| 250 | 15 | 05A 15A0 250C |

| 250 | 30 | 05A 30A0 250C |

| 250 | 40 | 05A 40A0 250C |

| 300 | 0,3 | 05A 98A0 300C |

| 300 | 0,5 | 05A 95A0 300C |

| 300 | 1 | 05A 01A0 300C |

| 300 | 2 | 05A 02A0 300C |

| 300 | 3 | 05A 03A0 300C |

| 300 | 5 | 05A 05A0 300C |

| 300 | 9 | 05A 09A0 300C |

| 300 | 12 | 05A 12A0 300C |

| 300 | 15 | 05A 15A0 300C |

| 300 | 30 | 05A 30A0 300C |

| 300 | 40 | 05A 40A0 300C |

| 400 | 0,3 | 05A 98A0 400C |

| 400 | 0,5 | 05A 95A0 400C |

| 400 | 1 | 05A 01A0 400C |

| 400 | 2 | 05A 02A0 400C |

| 400 | 3 | 05A 03A0 400C |

| 400 | 5 | 05A 05A0 400C |

| 400 | 9 | 05A 09A0 400C |

| 400 | 12 | 05A 12A0 400C |

| 400 | 15 | 05A 15A0 400C |

| 400 | 30 | 05A 30A0 400C |

| 400 | 40 | 05A 40A0 400C |

Diamond HC abrasive films

High concentration abrasive films. Available in different grains from 0.5 µm to 45 µm, they generate excellent flatness and finishing results. The uniformity of the abrasive layer ensures great regularity of the polishing process and prolonged durability of the disc.

Easy to use, the strong stock removal and polishing quality enables you to significantly reduce your sample polishing time. They can be used with all material types.

Recommended lubricants: FLUIDE 712 water-based or FLUIDE 705 oil-based.

| 5 pieces | Self-adhesive |

Non adhesive |

||

| Ø in mm |

Color | µm | Ref. | Ref. |

| 200 | 45 | 05D 45A0 2005 | 05D 45N0 2005 | |

| 200 | 30 | 05D 30A0 2005 | 05D 30N0 2005 | |

| 200 | 15 | 05D 15A0 2005 | 05D 15N0 2005 | |

| 200 | 9 | 05D 09A0 2005 | 05D 09N0 2005 | |

| 200 | 6 | 05D 06A0 2005 | 05D 06N0 2005 | |

| 200 | 3 | 05D 03A0 2005 | 05D 03N0 2005 | |

| 200 | 1 | 05D 01A0 2005 | 05D 01N0 2005 | |

| 200 | 0,5 | 05D 95A0 2005 | 05D 95N0 2005 | |

| 250 | 45 | 05D 45A0 2505 | 05D 45N0 2505 | |

| 250 | 30 | 05D 30A0 2505 | 05D 30N0 2505 | |

| 250 | 15 | 05D 15A0 2505 | 05D 15N0 2505 | |

| 250 | 9 | 05D 09A0 2505 | 05D 09N0 2505 | |

| 250 | 6 | 05D 06A0 2505 | 05D 06N0 2505 | |

| 250 | 3 | 05D 03A0 2505 | 05D 03N0 2505 | |

| 250 | 1 | 05D 01A0 2505 | 05D 01N0 2505 | |

| 250 | 0,5 | 05D 95A0 2505 | 05D 95N0 2505 | |

| 300 | 45 | 05D 45A0 3005 | 05D 45N0 3005 | |

| 300 | 30 | 05D 30A0 3005 | 05D 30N0 3005 | |

| 300 | 15 | 05D 15A0 3005 | 05D 15N0 3005 | |

| 300 | 9 | 05D 09A0 3005 | 05D 09N0 3005 | |

| 300 | 6 | 05D 06A0 3005 | 05D 06N0 3005 | |

| 300 | 3 | 05D 03A0 3005 | 05D 03N0 3005 | |

| 300 | 1 | 05D 01A0 3005 | 05D 01N0 3005 | |

| 300 | 0,5 | 05D 95A0 3005 | 05D 95N0 3005 | |

| 400 | 45 | 05D 45A0 4005 | 05D 45N0 4005 | |

| 400 | 30 | 05D 30A0 4005 | 05D 30N0 4005 | |

| 400 | 15 | 05D 15A0 4005 | 05D 15N0 4005 | |

| 400 | 9 | 05D 09A0 4005 | 05D 09N0 4005 | |

| 400 | 6 | 05D 06A0 4005 | 05D 06N0 4005 | |

| 400 | 3 | 05D 03A0 4005 | 05D 03N0 4005 | |

| 400 | 1 | 05D 01A0 4005 | 05D 01N0 4005 | |

| 400 | 0,5 | 05D 95A0 4005 | 05D 95N0 4005 |