METALLOGRAPHY

Faced with the constant evolution of the materials and the quality standards, LAM PLAN is a reference partner for the preparation of the samples for the metallographic analysis.

Our technical solutions and our customised methods will ensure you reliable and reproducible results. We are fully committed to the quality of the samples.

The LAM PLAN test laboratory will guarantee you a response adapted to your needs in surface preparation. This service relies on our range of innovative products and our in-depth experience of the various polishing and super finish trades.

Cutting

Metallographically cutting off the part allows not only sampling the material, but also observing the material’s structure at a specific spot.

The preparation of metallographic samples requires a precision cutting off in a wide variety of materials.

A good lubrication is necessary to cool the cutting wheel and prevent the burning of the parts. In addition, the environment of a metallography laboratory imposes cleanliness and safety criteria to which your cut-off equipment must comply.

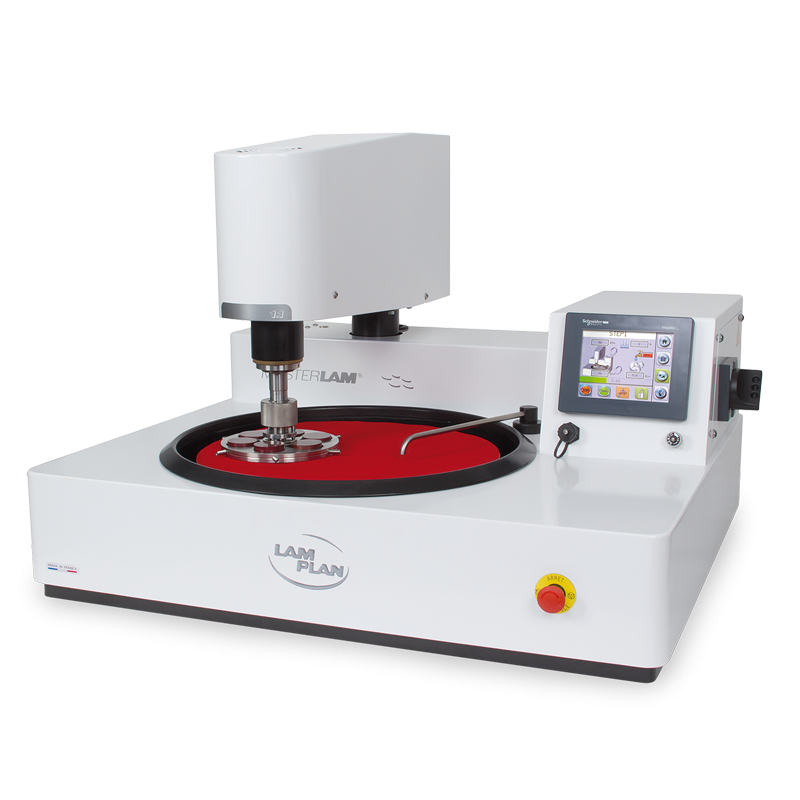

Mounting

Embedding allows limiting edge stresses during the polishing step. This operation will also allow you:

- In manual polishing: to facilitate the holding of the sample

- In automatic polishing: to place several samples together in a sample holder under optimum tightening conditions.

All mounting products

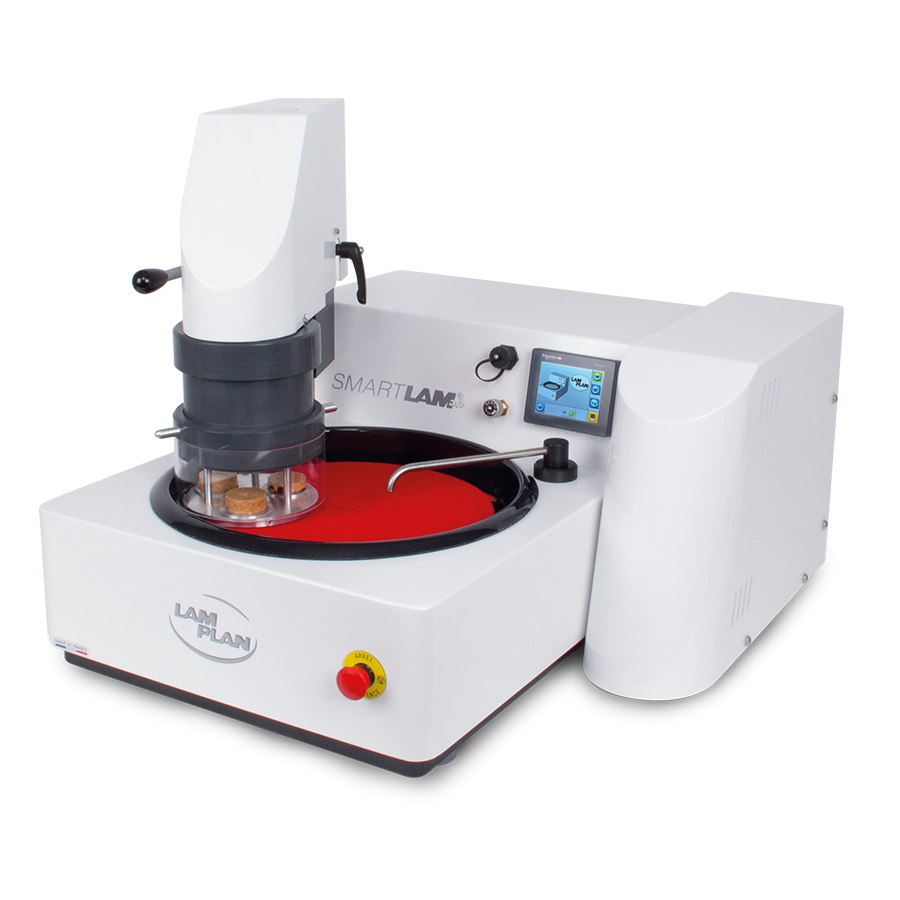

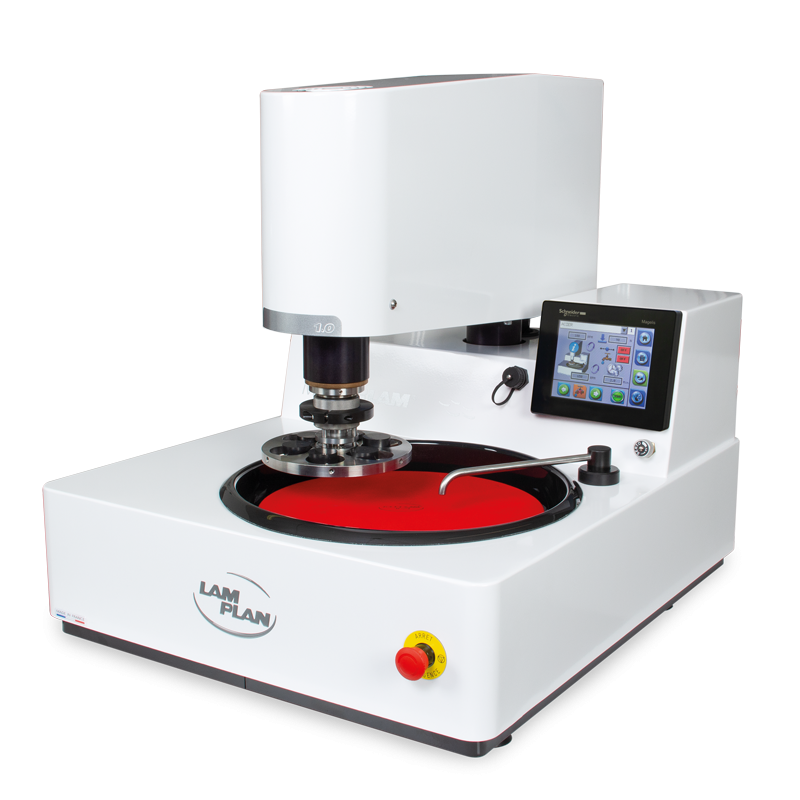

Prepolishing & polishing

Grinding and prepolishing are crucial steps in the preparation of a metallographic sample.

It is the quality of these steps which will condition and optimise the rest of the process.

At the end of the prepolishing step, the sample’s aspect must be uniform and regular without any alteration of the inherent flatness or the material.