CUTLAM®5.0

The CUTLAM®5.0 is a pedestal-mounted machine with an integrated recirculation/decanter tank. It represents the ultimate equipment in terms of high-capacity programmable automatic cutting machines. Power and advanced control of the cutting steps will guarantee first class efficiency and productivity.

-

Wheel Ø355 (400 option) mm

-

Rotational speedfrom 1000 to 4000 rpm

-

Max cutting capacityØ 127 mm

-

Dim. W x H x D877 x 1727 x 1800 mm

Wheel and table movements

Fitted in standard with a Ø 355 mm wheel, which produces an automatic vertical and longitudinal movement. The automatic transverse movement is carried out by an optional cross-feed table.

Controls

Programming is performed via a large touch screen with a graphical interface that ensures you an intuitive use. Cutting parameters are continuously visible on the screen. Fast positioning of the cutting point is provided by the use of a joystick.

The internal memory allows you to store 300 programs that can be transferred via USB.

Easy programming

Depending on the location of the sample on the table, and on its dimensions, the screen will indicate the various necessary and possible moves in order to complete the cut. This data can then be saved.

All cutting modes are possible

– Automatic or manual cutting.

– Continuous automatic cutting with ingenious feed speed control:

- The feed speed is pre-set, and will be automatically reduced if the load on the cutting wheel increases. The pre-set speed returns when the load on the screen decreases.

- It improves the quality of the cut by limiting the thermal damages over the samples.

- It is suitable for irregular samples and/or material with heterogeneous hardness.

- It prevents the wheel from breaking in case of overload.

- It allows you to work at maximum speed without any risk of damage.

– Automatic sequential cutting for maximum cooling.

– Plunge cutting, horizontal feed cutting and oscillating cutting.

– Repetitive parallel cutting.

Equipment

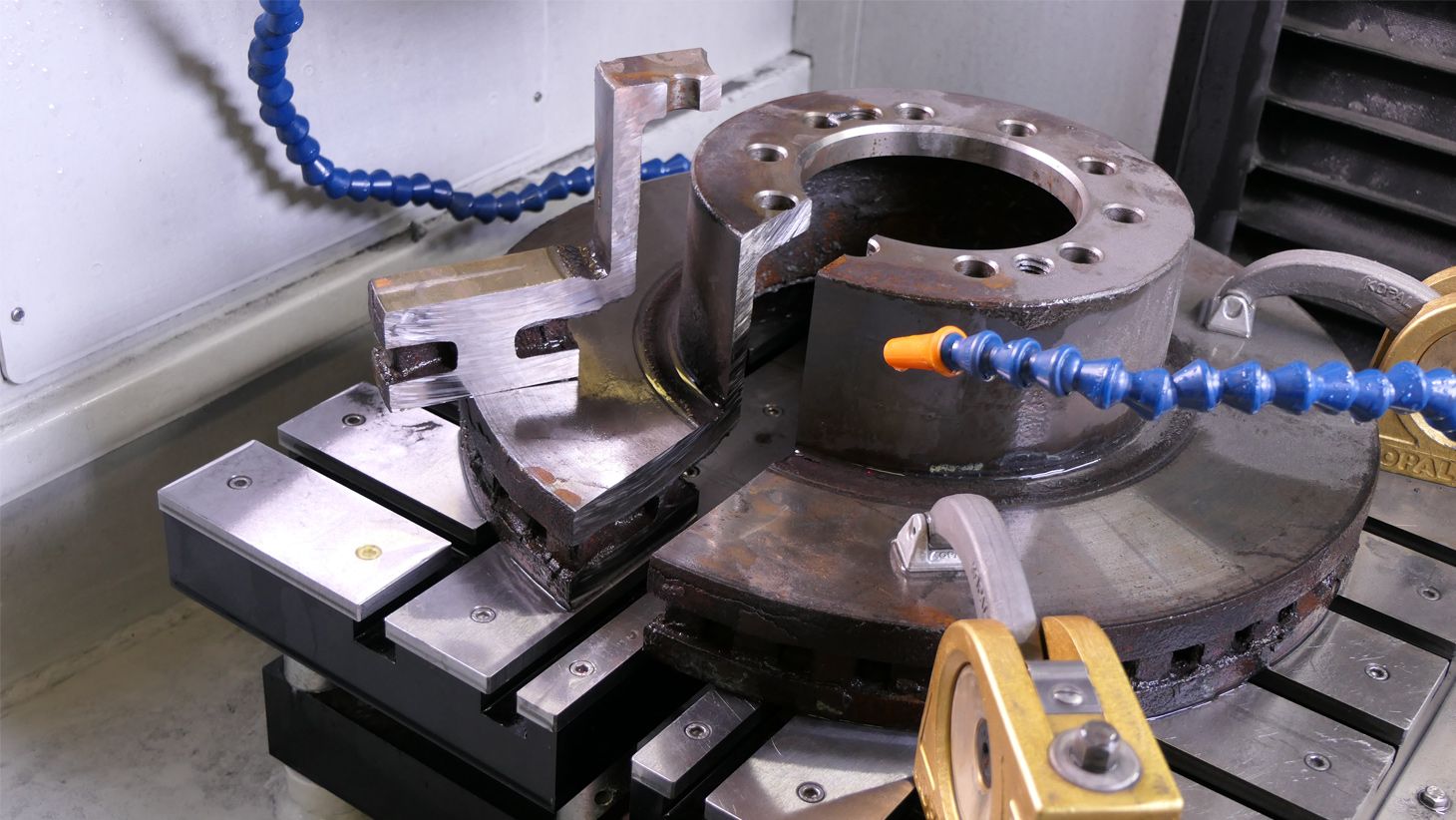

A high-capacity, independent cooling/recirculation system (140 litres) is located under the machine. The multipoint nozzles insure excellent cooling of the sample and the cutting wheel even during intensive use.

Fast cleaning is made possible thanks to an exterior shower head and a carefully designed cutting chamber.

The wide cutting table: W 408 x D 422 mm is composed of two independent parts. 4 longitudinal grooves and 6 transversal grooves that allow to fix all kind of clamping systems available as options or on the market.

Design and advanced technology

Technical characteristics and equipment

*space under disc

Options

-

Machine for cut-off wheel Ø 400 mm60 CT503 00

-

Positioning laser60 CT506 00

Machine variations

-

Machine with motorised cross-feed table (X axis) stroke 120 mm, accuracy 0,05 mm60 CT50A 10

-

Machine with motorised cross-feed table (X axis) stroke 380 mm, accuracy 0,05 mm60 CT50A 100

Downloads

Technical data CUTLAM®5.0

Cut-off wheel Ø | 355 mm (400 mm optional) |

Shaft Ø | 25,4 mm |

Standard flanges Ø | 100 mm |

Max cutting capacity | Ø 127 mm (with Ø 355 mm wheel) + opening on left and right hand side for long parts |

Passage under the wheel | 252,5 mm (Ø 355 mm wheel) |

Vertical movement | Z axis stroke 350 mm, speed from 0,1 to 25 mm/sec, speed advanced 50 mm/sec |

Longitudinal movement | Y axis stroke 350 mm speed from 0,1 to 25 mm/sec

advanced speed 50 mm/sec |

Transversal movement | X axis stroke 120 mm (optional) |

Lubrification | Recirculation system, 140 litres, on casters Cleaning system integrated, with a shower head outside of the cutting chamber |

Motor power | 5,5 kW |

Rotational speed | Variable, from 1000 to 4000 rpm |

Table | Treated aluminium and interchangeable stainless Steel plate, W 408 x D 422 mm |

Type of groove | T-slots 12 mm (4 longitudinal, 6 transversal) |

Lightening | LED strip |

Protection | Cover with locking system |

Body | Steel coated with epoxy paint |

Pneumatic feeding | 6 bars filtered 5 µ |

Electrical power | 12 kW combined |

Electrical consumption | 32 Ah |

Voltage | 400 Volts – 50 Hz (three-phase + ground) |

Dim. W x H x D | 877 (+ 600 mm with control panel) x 1727 x 1800 mm (H. cover open 2272 mm) |

Weight | 750 kg |

Reference | 60 CT50A 00 |

Available accessories

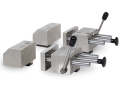

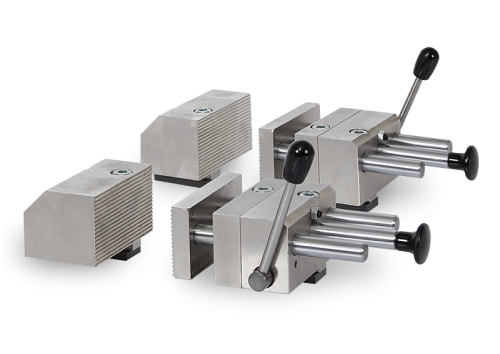

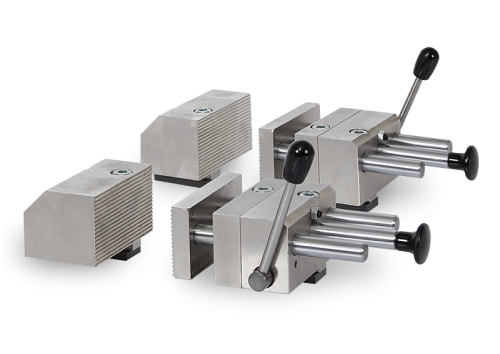

Double vice with fast tightening system

(left and right side of the wheel)

2 x 2 elements vice, without sole, to obtain maximal length clamping.

Jaws: W 80 x H 45 mm

T-slot 12 mm screw included.

Left and right levers.

Double vice with fast tightening system

(left and right side of the wheel)

2 x 2 element vice, without sole, to obtain maximal length clamping.

Jaws: W 80 x H 70 mm

T-slot 12 mm screw included.

Left and right levers.

Double vice with screw tightening system

(left and right side of the wheel)

2 x 2 element vice, without sole, to obtain maximal length clamping.

Jaws: W 80 x H 45 mm

T-slot 12 mm screw included.

Left and right levers.

Universal clamping KOPAL 61

Lift for KOPAL 61

Long cam for KOPAL 61

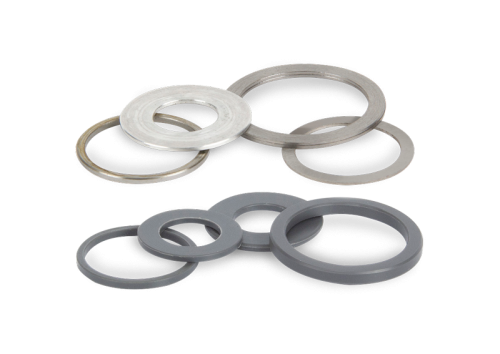

Steel & PVC adaptor rings for cut-off wheels

- Steel Ø 32 x 25,4 mm (5 units) – 60 00373 90

- PVC Ø 32 x 25,4 mm (5 units) – 60 00374 90

Oil mist extraction device A1

The LAM PLAN vaccuming system extracts the “polluted” air inside the cutting chamber of your cutting machine.

A special multilayer filter will stop the smallest polluting particles, thus preventing their dispersion into the atmosphere. The cutting fluid, in the liquid state, is returned to the cutting machine recirculation tank to be reused. (An evacuation is provided for this purpose on the vacuuming system). A cartridge post-filter, located above the suction system, ensures a high filtration level, up to 99.97%. An adapter part (LAM PLAN code 60CT20820) is provided to adapt the suction hose to the canopy of the LAM PLAN cutting machine. The vacuuming system is mounted on a trolley with wheels, allowing an easy positioning. A drain valve, located in the trolley, collects the condensate.