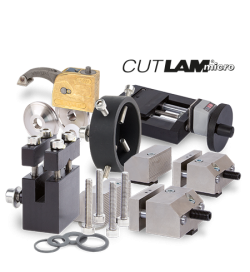

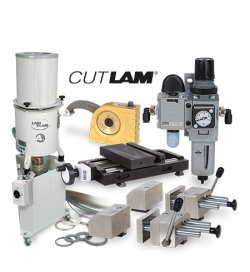

CUTLAM®micro 3.0

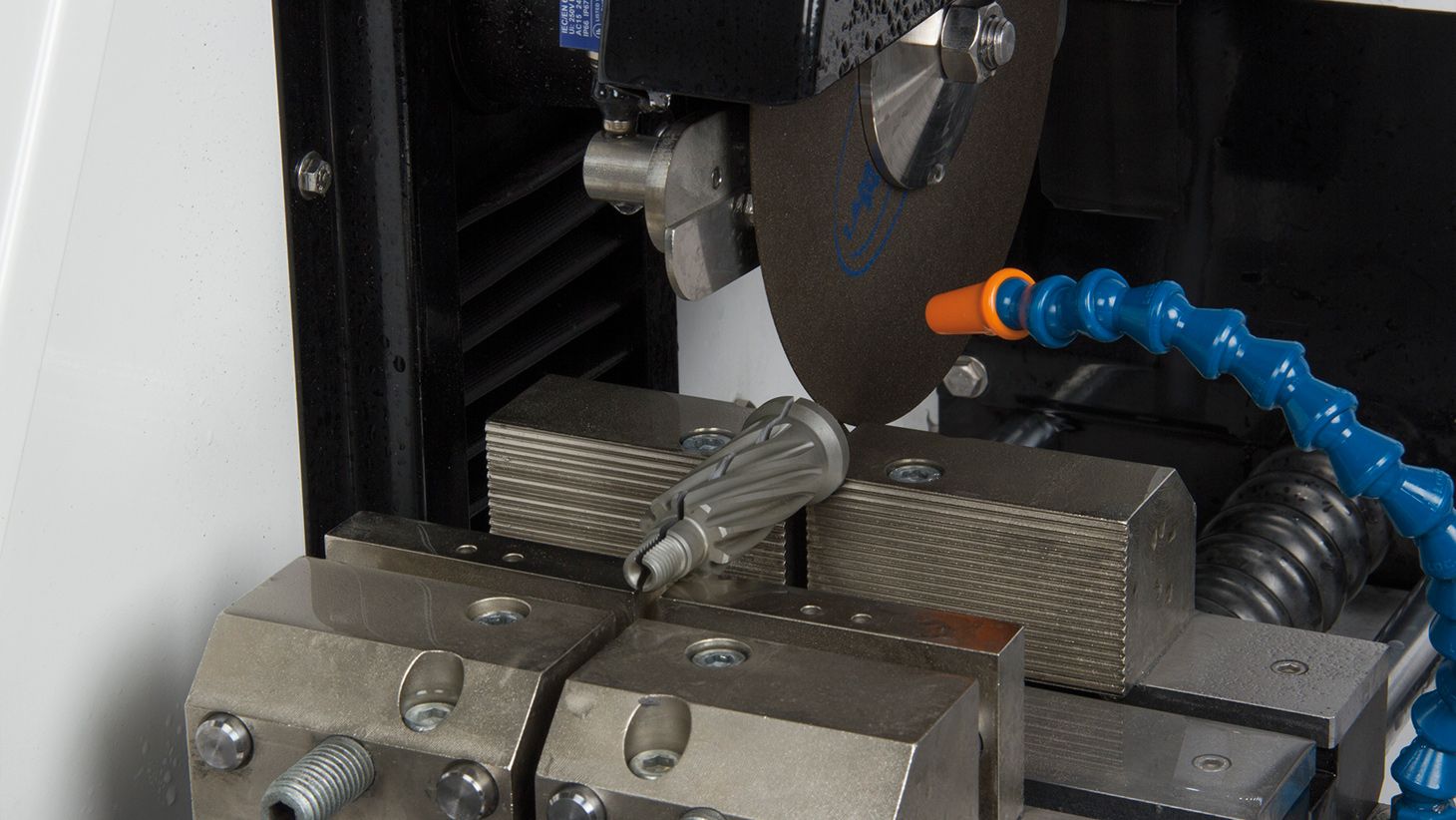

The CUTLAM®micro 3.0 is a bench-top cut-off machine for laboratories looking for an automatic machine for long, high-precision cuts, offering high capacity in a compact package. Thanks to the many ways in which the disc and table can be moved, even the most complex jobs are possible.

-

Wheel Ø75 to 200 mm

-

Rotational speedfrom 1000 to 4000 rpm

-

Max cutting capacityØ 75 mm

-

Dim. W x H x D620 x 470 x 750 mm

Large capacity compact cutting machine

It is fitted with a large: 320 x 540 mm chamber, and equipped with a grooved aluminium table, sized 210 x 210 mm, and stainless steel interchangeable pallets. The large capacity of the CUTLAM®micro 3.0 relies on the use of 200 mm cut-off wheel, combined with a vertical movement range of 100 mm (Z axis) and a longitudinal range of 270 mm (Y axis).

Precision

Axis positioning accuracy is 0.01 mm, which can be viewed on screen. Feed speeds during the cutting phase are adjustable from 0.1 to 20 mm/sec. Use of the intelligent feed management system (see next page for an explanation of this device) will automatically reduce the axis feed rate to a minimum value of 0.02 mm/sec.

Always in control

A large touchscreen with a graphical user interface makes it easy to get to grips with the machine intuitively. All positioning and cutting parameters are continuously visible on the screen. A joystick is used to quickly position the cutting point. In automatic and semi-automatic mode, an estimated cutting time is displayed.

2 cutting modes are available: manual and automatic.

Efficiency: 5 key points for higher productivity

- Powerful motor of 1,1 kW.

- Sequential cutting mode for a maximum cooling.

- Ingenious feed speed control:

• The feed speed is pre-set, and will be automatically reduced if the load on the cutting wheel increases. The pre-set speed returns when the load on the wheel decreases.

• It improves the quality of the cut by limiting the heat damages on the samples.

• Suitable for irregular samples and/or materials with heterogeneous hardness.

• It prevents the wheel from breaking in case of overload.

• It allows you to always work at maximum speed without any risk of damage. - Optional cross-feed table (X axis) manual or motorised for repetitive parallel cuts.

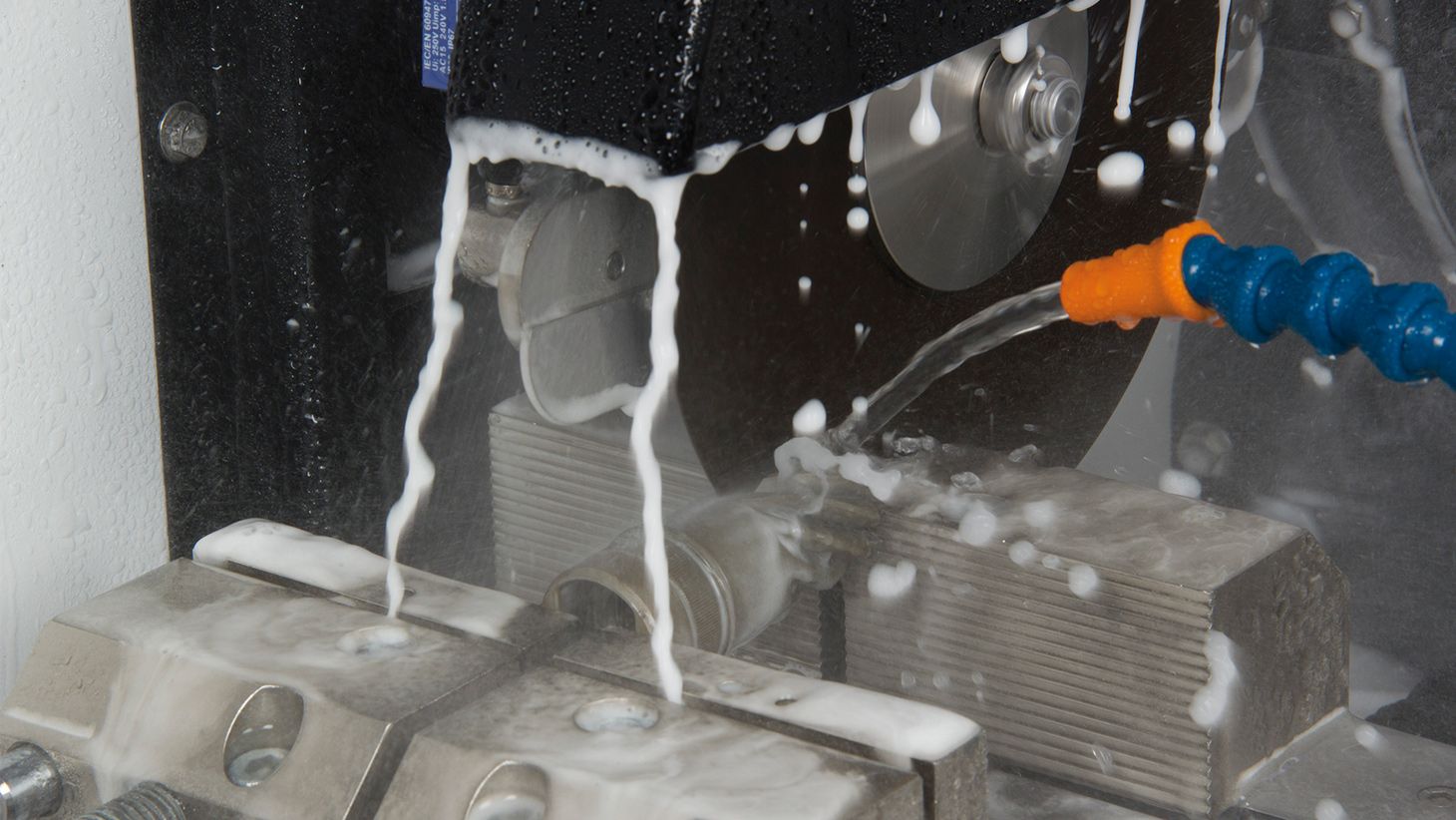

- Independent lubrication/cooling system, composed of a 100 µ washable filter, and a 30 litres sedimentation tank with multi-point nozzle, insures excellent cooling of the sample and the cutting wheel even during intensive use.

Design and advanced technology

Technical characteristics and equipment

*space under wheel

Tool for axial cutting of Ø 4 mm parts

Tool for axial cutting of Ø 4 mm parts

-

This device, used in conjunction with quick release clamps, enables manual positioning following the X axis, ensuring cutting precision and repeatability.

Ref. 60 CTM03 93

Downloads

Technical data CUTLAM®micro 3.0

Cut-off wheel Ø | 75 to 200 mm |

Shaft Ø | 12,7 mm |

Standard flanges Ø | 75 mm |

Passage under the wheel | 62 mm (with a Ø 200 mm disc) |

Max cutting capacity | Ø 62 mm (with a Ø 200 mm disc) |

Vertical movement | Z axis 100 mm automatic |

Longitudinal movement | Y axis 270 mm automatic |

Transversal movement | X axis 55 mm manual or 50 mm motorised (optional) |

Cooling/ Lubrication | Decantation tank, 2 chambers, Input 100 µm filter, Pump 800 L/hour driven |

Motor power | 1,1 kW |

Rotational speed | Variable, from 1000 to 4000 rpm. |

Cutting modes | Manual, semi-automatic, automatic |

Feed speed control | 0,1 to 20 mm/sec. programmable Automatic control of speed / power continuous or sequential |

Lightening | LED |

Protection | Transparent cover with locking system |

Voltage | 230 V – 50 Hz simple phase |

Dimensions W x H x D | 620 x 470 x 750 mm (H cover open 812 mm) |

Weight | 80 kg |

Reference | 60 CTM30 00 |

Available accessories

CUTLAM® support cabinet

Solid painted-steel piece of furniture specially designed for CUTLAM® products.

It contains a storage door for tools and cut-off wheels, a drawer on top and a space for the recirculation tank. This piece of furniture is stable and has adjustable feet.

Dimensions : L x H x D : 630 x 800 x 835 mm.

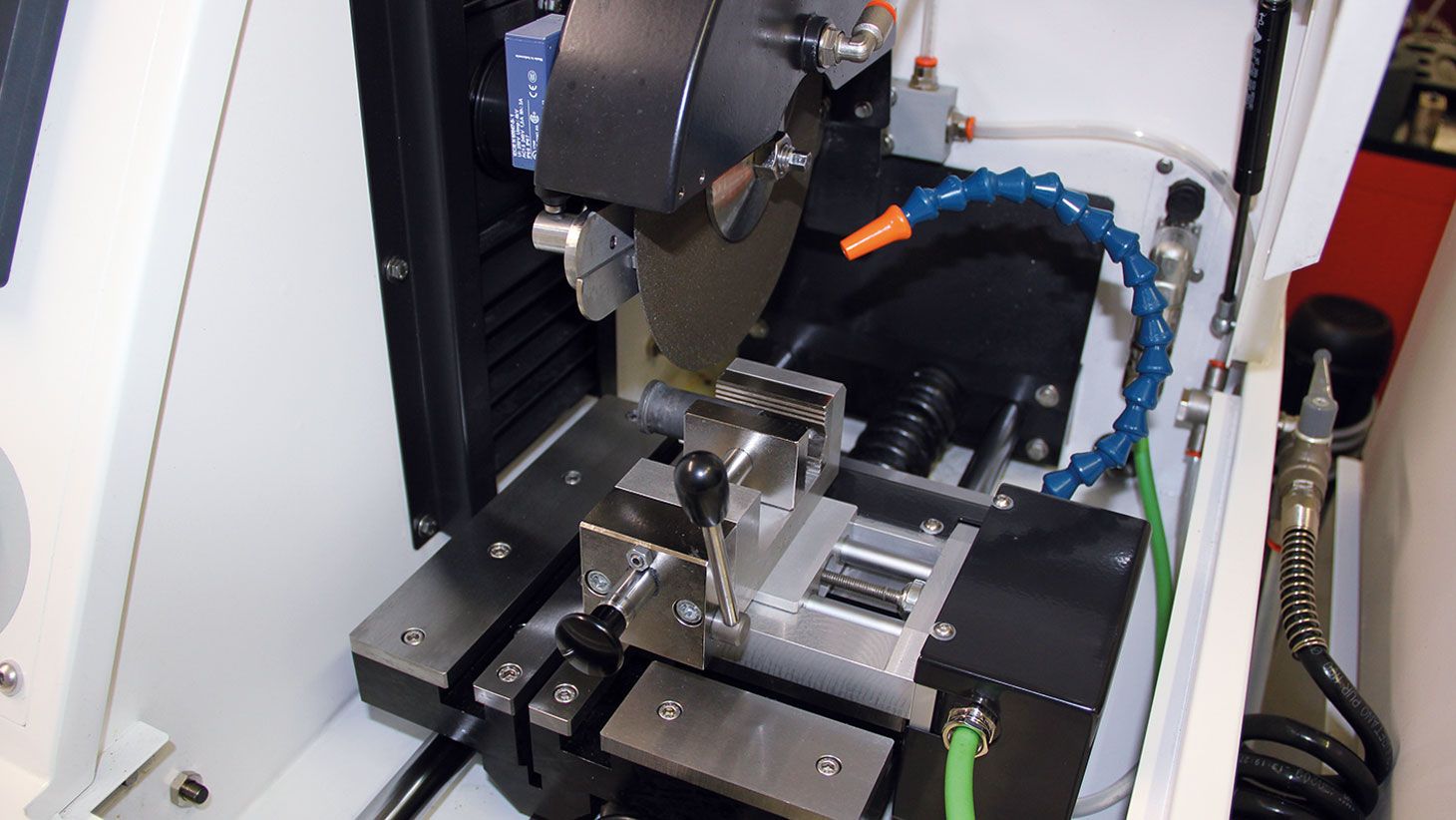

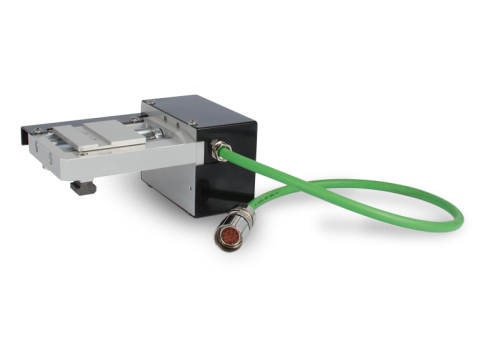

Automatic transversal table (X movement)

Stroke: 50 mm

Precision: 0,01 mm

Transversal table (X movement) to execute parallel cuts

Manual movement with a roller

Stroke: 55 mm

Precision: 0,01 mm.

Can receive right vice reference 60 CTM32 00.

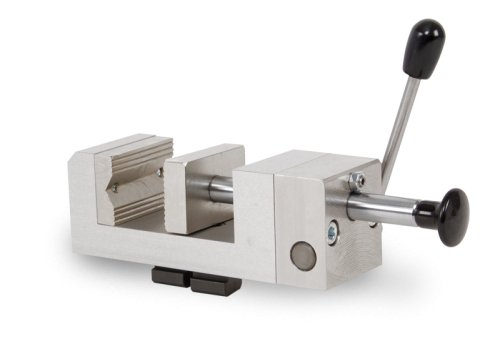

Small right vice with fast tightening system

Stroke: 53 mm

Jaws: W 47 x H 32 mm

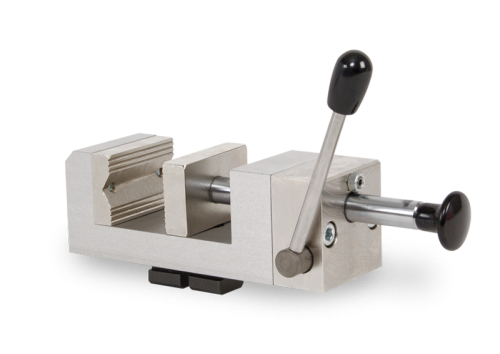

Small left vice with fast tightening system

Stroke: 53 mm

Jaws: W 47 x H 32 mm

Double vice with screw tightening system (left and right side of the wheel)

2 x 2 element vice, without sole, to obtain maximal length clamping.

Jaws: W 80 x H 45 mm

T-slot 12 mm screw included.

Left and right levers.

Universal clamping KOPAL 54

Set of flanges

- Set of flanges Ø 35 mm for cut-off wheels Ø 75 to 100 mm – 60 CTM01 10

- Set of flanges Ø 50 mm for cut-off wheels Ø 125 to 150 mm – 60 CTM01 20

- Set of flanges Ø 75 mm for cut-off wheels until Ø 230 mm – 60 CTM01 30

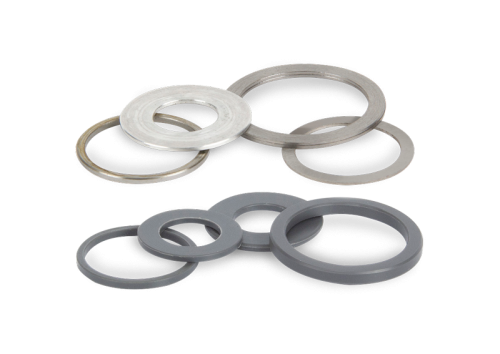

Steel & PVC adaptor rings for cut-off wheels

- Steel Ø 22 x 12,7 mm (5 units) – 60 00608 90

- PVC Ø 22 x 12,7 mm (5 units) – 60 00609 90

- Steel Ø 25,4 x 12,7 mm (5 units) – 60 00369 90

- PVC Ø 25,4 x 12,7 mm (5 units) – 60 00370 90