with PE128

Grinder/polisher for pre-polishing and thicknessing

M.M.9400 with PE128

The LAM PLAN M.M.9400 grinding machine combined with the PE128 mounting is the ideal equipment for making reference faces or for precise thicknessing.

-

Plate Ø381 mm (Ø 400 mm optional)

-

Plate rotation speedfrom 20 to 120 rpm

-

Ø Inner ring Ø140 mm

-

Weight75 kg

The M.M.9400 is a solution for integrating a means of finishing flat surfaces into your workshop at a contained price. The machine’s compact dimensions and ergonomic controls are still there, but it has become more rigid and even more versatile.

It can be fitted with a wide range of accessories to adapt your equipment to your needs. Integrated control of LAM PLAN feeders, recipe memory and motorised drive are just some of the possibilities.

Versatility

The M.M.9400 can be fitted with cast iron, DIALAM®, NEW LAM® M’M’ or FAS® platens, enabling you to achieve all types of surface finish defined in your specifications (e.g. honing, thickness adjustment, honing, polishing, etc.). It is also perfectly suited to your maintenance needs on all sealing parts (e.g. lapping of flaps, safety valves or small mechanical seals).

Design and advanced technology

Technical characteristics

and equipment

New configuration and improvements

• More rigid welded tubular steel chassis, stainless steel tank,

• Ergonomically improved controls (better visibility of screen in working position),

• 4.3’ touch screen,

• Programme import/export on USB key,

• Multiple attachment points for accessories, such as dosing devices, jib, etc,

• Memory for 30 recipes,

• Mobile water inlet controlled by solenoid valve,

• Improved connectivity, ability to control 3 dispensers, remote maintenance facility.

Downloads

Technical data M.M.9400

Plate Ø | 381 mm (Ø 400 mm optional) |

Inner ring Ø | 140 mm |

Capacity per ring | 1 part Ø130 mm or 170 parts Ø 5 mm |

Number of rings | 3 |

Electric power supply | 230 V single-phase |

Motor Power | 0.75 kW |

Control | 4.3″ touch screen |

Plate rotation speed | From 20 to 120 rpm |

Dim. (W x H x D) | 625 x 720 x 365 mm |

Weight (without plate) | 75 kg |

Abrasive distribution system | Optional |

Reference | 10 09400 00 |

Available accessories

Dosing unit type 709

Peristaltic model dedicated to LAM PLAN machines.

- Capacity : 2 x 500 cc including 1 with agitator

- Electric power supply : 220V single phase + 24 V input for control

- Pump flow rate : 0,5 ml/seconde

- Distribution system : nozzles not included

Dosing unit type 710

Peristaltic model dedicated to LAM PLAN machines, recommended for oil-based products.

- Capacity : 2 x 500 cc including 1 with agitator

- Electric power supply : 220V single phase + 24 V input for control

- Pump flow rate : 0,5 ml/seconde

- Distribution system : nozzles not included

Dosing unit type 719

Venturi model dedicated to LAM PLAN machines.

- Capacity : 2 x 500 cc including 1 with agitator

- Electric power supply : 220V single phase + 24 V input for control

- Pump flow rate : N.C.

- Distribution system : nozzles not included

Autonomous dosing unit M.M.909 – Peristaltic

- Distribution system: 3 standard peristaltic pumps with an outlet to drive an external pump

- Control: Touch screen

- Electrical power supply: 220 V single-phase – 50 Hz

- Dosing machine communication: 1 x 24 V input for machine servoing

| Designation |

Qty. | Dim. | Ref. |

| Dosing unit M.M.909 ADAPTABLE VERSION With a manual start/stop button |

1 | with 3 glass bottles 500 cc | 08 03799 00 |

| Stirrer | 1 | for glass bottle 500 cc | 08 02816 00 |

Autonomous dosing unit M.M.909 HV – Peristaltic

- Distribution system: 2 standard peristaltic pumps, 1 large flow pump for high viscosity liquids and an outlet to drive an external pump

- Control: Touch screen

- Electrical power supply: 220 V single-phase – 50 Hz

- Dosing machine communication: 1 x 24 V input for machine servoing

| Designation |

Qty. | Dim. | Ref. |

| Dosing unit M.M.909 HV | 1 | with 3 glass bottles 500 cc | 08 00799100 |

| Stirrer | 1 | for glass bottle 500 cc | 08 02816 00 |

Support cabinet

Height: 73 cm

1 door

3 compartments

MESUREO: Stock removal measurement

A system enabling obtention of flat surfaces at less than one micron, combined with a parallelism of quality between the lapped face and a reference.

The MESUREO is comprised of a perfectly flat pressure disc, which is able to transpose on a vertical axis, therefore producing pressure on the opposite face of the surface to be lapped.

The pressure plate is guided by a high precision ball bearing socket. Also, at the end of the polishing cycle, the parts contained by this tool will have a parallelism inferior to 5 microns.

The pressure surface is ceramic, assuring a long life, with no risk of metallic contamination. Finally, this tool is equipped with a wireless sensor, allowing visualisation of material removal in real time on a PC placed next to the lapping machine to which this device is connected.

The target dimension can be programmed. Therefore, the operator, via an intuitive colour range on the monitor, can instantly visualise whether or not the parts are within the defined thickness tolerance.

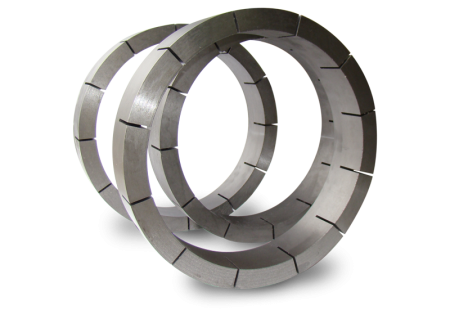

Cast iron conditioning rings 15″

We carefully select special high quality cast iron for optimum, durable results.

Suitable for all lapping machines, whatever the brand or size.

Available from stock or produced to order.

| Ø (mm) | Qty | Ref. | |

| Ext. | Int. | ||

| 178 | 140 | 1 | U178 A0381 |

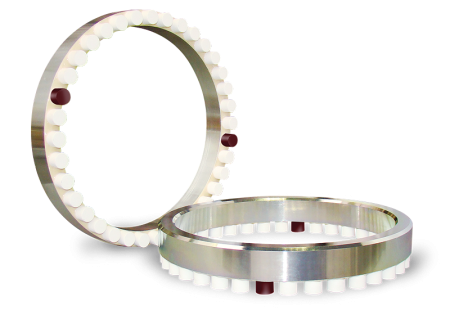

Anneaux d’autorodage céramique SPYLAP®

Prévenez les problèmes de déformation mécanique. Les anneaux céramique vous permettent de préserver la planéité des plateaux, de maîtriser leur échauffement, tout en limitant la pollution grâce à l’absence de graphite.

Le détecteur SPYLAP® permet à l’utilisateur de prévenir visuellement une déformation mécanique trop importante du support de rodage (ou de polissage) et des pièces à roder. Le SPYLAP® capte en permanence la température du support et il passe du noir au rouge à une température précise prédéfinie.

| Ø en mm | Qté | Réf. | |

| Ext. | Int. | ||

| 182 | 140 | 1 | 08 83562 10 |

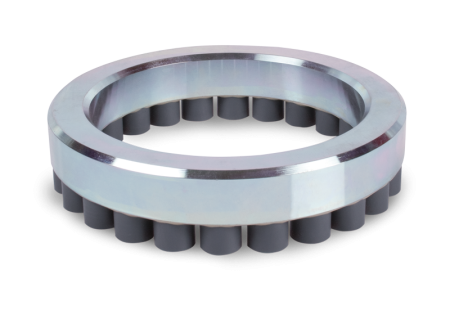

Anneaux plastique

| Ø en mm | Qté | Réf. | |

| Ext. | Int. | ||

| 182 | 140 | 1 | 08 83512 00 |