Hot mounting resins

To respond to all metallographic control and research situations, LAM PLAN developed and tested a range of hot mounting resins which allow obtaining perfectly adapted mountings regardless.

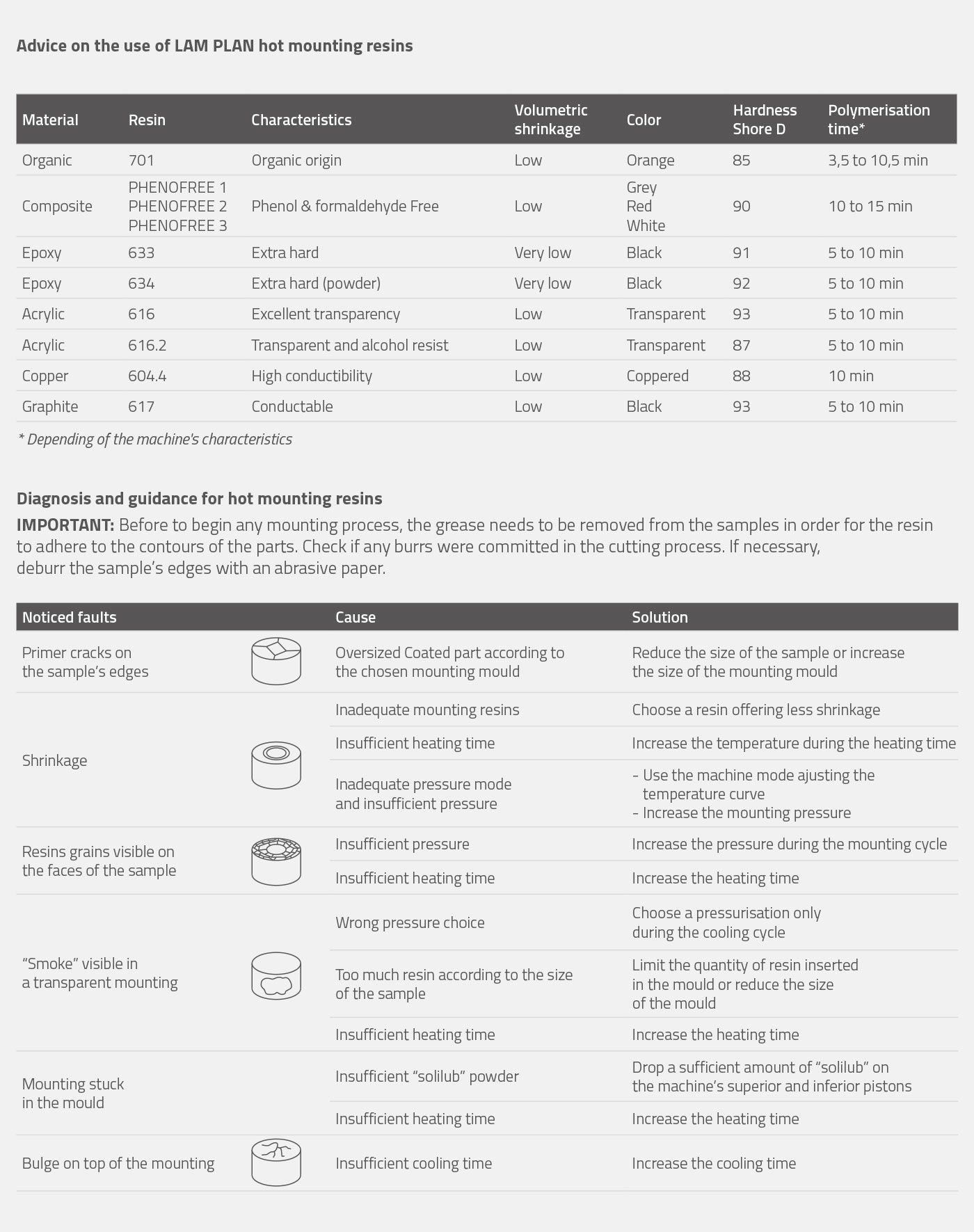

Organic resin

The new ORGANIC 701 hot mounting resin completes our list of consumables for the preparation of metallographic samples.

In the dynamic field of materials science and metallography, developing environmentally-friendly solutions without compromising performance is a constant challenge. That’s why we have added ORGANIC 701 to our range.

This resin offers a range of benefits, including dust-free pellet form, sustainable raw materials from responsible sources, optimum hardness of 85 Shore D and low shrinkage. ORGANIC 701 is an excellent alternative to conventional phenolic or epoxy resins.

Organic resin 701

| Characteristics |

Qty/kg | Ref. |

| Orange granules, polyester base with wood filler. Low shrinkage, hard. | 2 | 06 00701 20 |

| 10 | 06 00701 10 |

PHENOFREE hot mounting resins

Phenol-free and formaldehyde-free thermosetting mounting resin

In line with its ecological commitment, LAM PLAN proposes on the market the first effective alternative to phenol metallographic mounting resins which are liable to release phenol (and/or formaldehyde) during baking.

The PHENOFREE mounting is intended for the technical mounting of all types of materials for material examinations or edge examinations. It smartly replaces the traditional phenol mounting resins with the same hardness and less shrinkage than a phenol mounting resins.

The range of PHENOFREE resins includes 3 coloured resins (grey, white and red) to make the identification of your metallographic samples easier. They are particularly adapted for the polishing of hard materials. The white Phenofree resin may prove to be in some cases a good alternative to the use of epoxy resins.

PHENOFREE 1

| Characteristics |

Qty/kg | Ref. |

| Grey composite powder Polyvalent, hard |

2,5 | 06 PF010 20 |

| 10 | 06 PF010 10 | |

| 25 | 06 PF010 50 |

PHENOFREE 2

| Characteristics |

Qty/kg | Ref. |

|

Red composite powder |

2,5 | 06 PF020 20 |

| 10 | 06 PF020 10 | |

| 25 | 06 PF020 50 |

PHENOFREE 3

| Characteristics |

Qty/kg | Ref. |

| Poudre composite blanche Polyvalente, extra dure |

2,5 | 06 PF030 20 |

| 10 | 06 PF030 10 | |

| 25 | 06 PF030 50 |

Epoxy hot mounting resins

The black epoxy mounting resin is filled with glass fibres with high mineral loads. It is ideal for mountings intended for edge examinations of hard to extra hard materials thanks to its resistance to abrasion, important hardness and absence of shrinkage.

Epoxy resin 633

| Characteristics |

Qty/kg | Ref. |

| Black epoxy pellet, glass-fibre reinforced Edges examinations Extra hardness – No shrinkage |

2,5 | 06 00633 20 |

| 10 | 06 00633 10 |

Epoxy resin 634

The 634 is a fine powder epoxy resin, used for examination of edged samples and complex parts.

| Characteristics |

Qty/kg | Ref. |

| Black epoxy powder Edge examinations on complex samples High hardness – No shrinkage |

2,5 | 06 00634 20 |

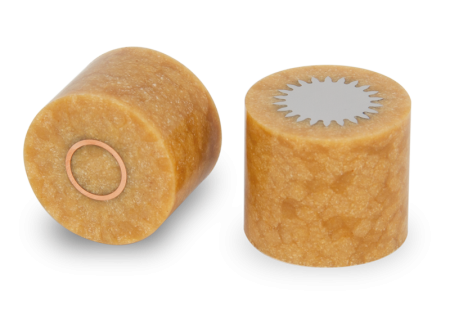

Acrylic hot mounting resins

Acrylic resin 616

The acrylic resin 616 is perfectly transparent and adapted to most materials.

Mainly used to view the evolution of the grinding of the sample.

| Characteristics |

Qty/kg | Ref. |

| Transparent acrylic powder Visualising the sample during and after the polishing All materials |

2,5 | 06 00616 20 |

| 10 | 06 00616 10 |

Acrylic resin 616.2

Perfectly transparent with no cotton effect, the acrylic resin 616.2 is resistant to alcohol, and therefore ideal for work with alcohol-based polishing products or requiring a cleaning phase with ethanol, isopropyl alcohol or other.

| Characteristics |

Qty/kg | Ref. |

| Transparent acrylic powder Visualising the sample during and after the polishing Water resistant |

2,5 | 06 06162 20 |

| 10 | 06 06162 10 |

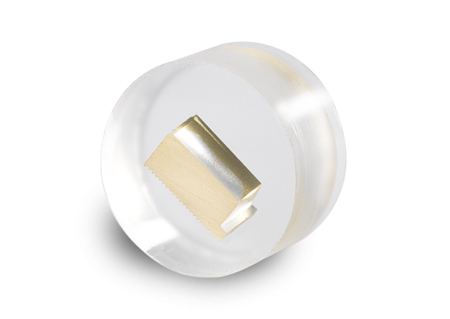

Copper hot mounting resin

Conductive resin suitable for electrolytic polishing and SEM examination. Based on pure copper of very homogeneous consistency, the conductivity of your mounts is optimised. The use of ultra-pure materials eliminates the risk of analysis errors.

Copper resin 604.4

| Characteristics |

Qty/kg | Ref. |

| Resinoid copper powder For electrolytic polishing |

2 | 06 00604 40 |

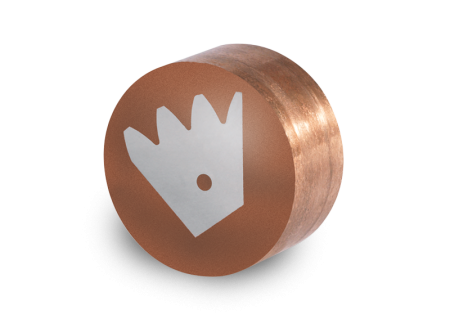

Graphite hot mounting resin

Graphite resin 617

Conductive phenolic mounting resin loaded with graphite (without copper and without metals or alloys) for SEM and TEM examinations.

| Characteristics |

Qty/kg | Ref. |

| Conductive black phenolic powder (graphite) For SEM examination |

1,5 | 06 00617 00 |

Guidance