PRESSLAM®1.1

The PRESSLAM®1.1 is a multi-purpose, easy-to-use, automatic hot mounting press that will allow you to achieve high production levels.

-

CapacityØ 25,4 to Ø 50 mm

-

Double mountingYes – all diameters

-

Pressure0 to 1,600 daN

-

Dim. W x H x D250 x 680 x 470 mm

All parameters are accessible via a 5.7” colour touch screen. The graphic interface guides you intuitively through the different settings, which you can then store and reuse at will. It is also possible to transfer predefined hot mounting parameters via the machine’s USB port. All phases are visible on the screen during the hot mounting cycle and can be modified at any time.

Each function can be adjusted separately and 4 pressurisation modes are available, along with a function reducing the amount of water used for cooling.

Once put in service the PRESSLAM®1.1 runs a pre-heating cycle that is cleared after 6 minutes without user intervention.

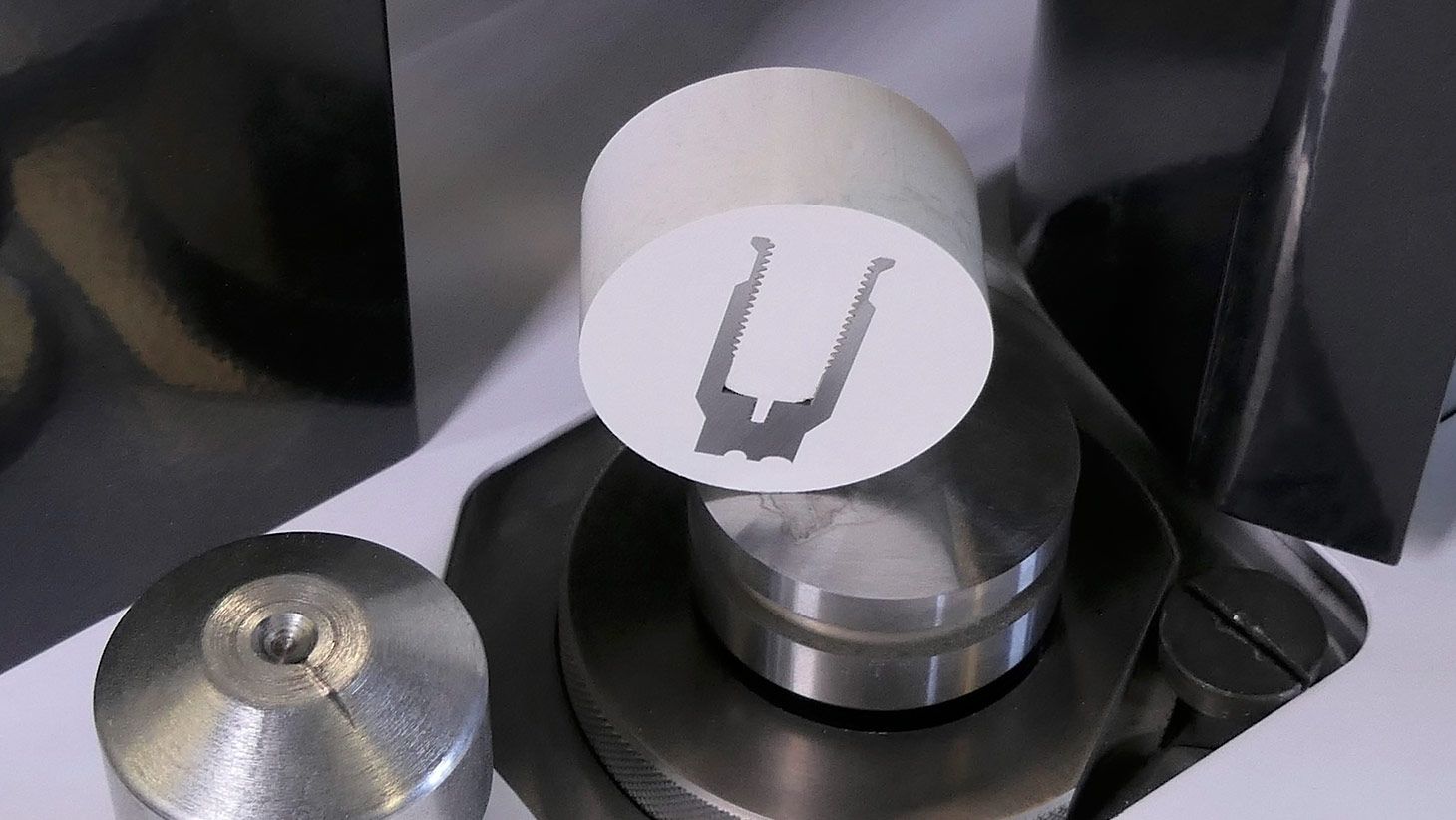

Access to mould is wide open for a sample positioning and filling facility. Quick and effortless, the locking/unlocking is realised by a cover and a ¼ turn locking lever.

Exclusive safety device

The expulsion of the sample after the mounting cycle is only possible when the safety cover is located in its intermediary position. This device creates a safety chamber in which the sample is protected in case of an eventual sticking situation.

The PRESSLAM®1.1 is equipped with a main heating unit which contains the removable cylinder. The standard heating unit covers diameters from 25,4 to 40 mm and a specific element is available for a 50 mm diameter.

The mounting chamber can be changed without any tools, nor electric or hydraulic connections.

It only takes a few minutes to change the complete heating unit.

This is a compact, easy-to-use machine. It will enable you to increase your productivity while maintaining excellent coating quality.

Design and advanced technology

Technical characteristics and equipment

Downloads

Technical data PRESSLAM®1.1

Capacity | Ø 25,4 to Ø 50 mm |

Heating system | 4 x 600 W around mould |

Temperature range | 20 to 200°C |

Heating cycle | 0 to 30 min |

Cooling cycle | 0 to 30 min |

Pressure | 0 to 1,600 daN |

Double mounting | Yes – all diameters |

Program back-up | 256 with USB connexion |

Pressurisation modes | 4 different modes |

Chamber closing | Half turned cover with a safety chamber |

Mould changing | Quick, without connectors- electric or hydraulic |

Pre-heating mode | Yes (cleared after 6 min without manipulation) |

Water saving | yes (up to 25%) |

Voltage | 230 V – 50 Hz single-phase |

Pneumatic feed | 6 to 10 bars |

Dim. W x H x D | 250 x 680 x 470 mm |

Weight | 72 kg |

Reference | 60 PL110 00 |

Available accessories

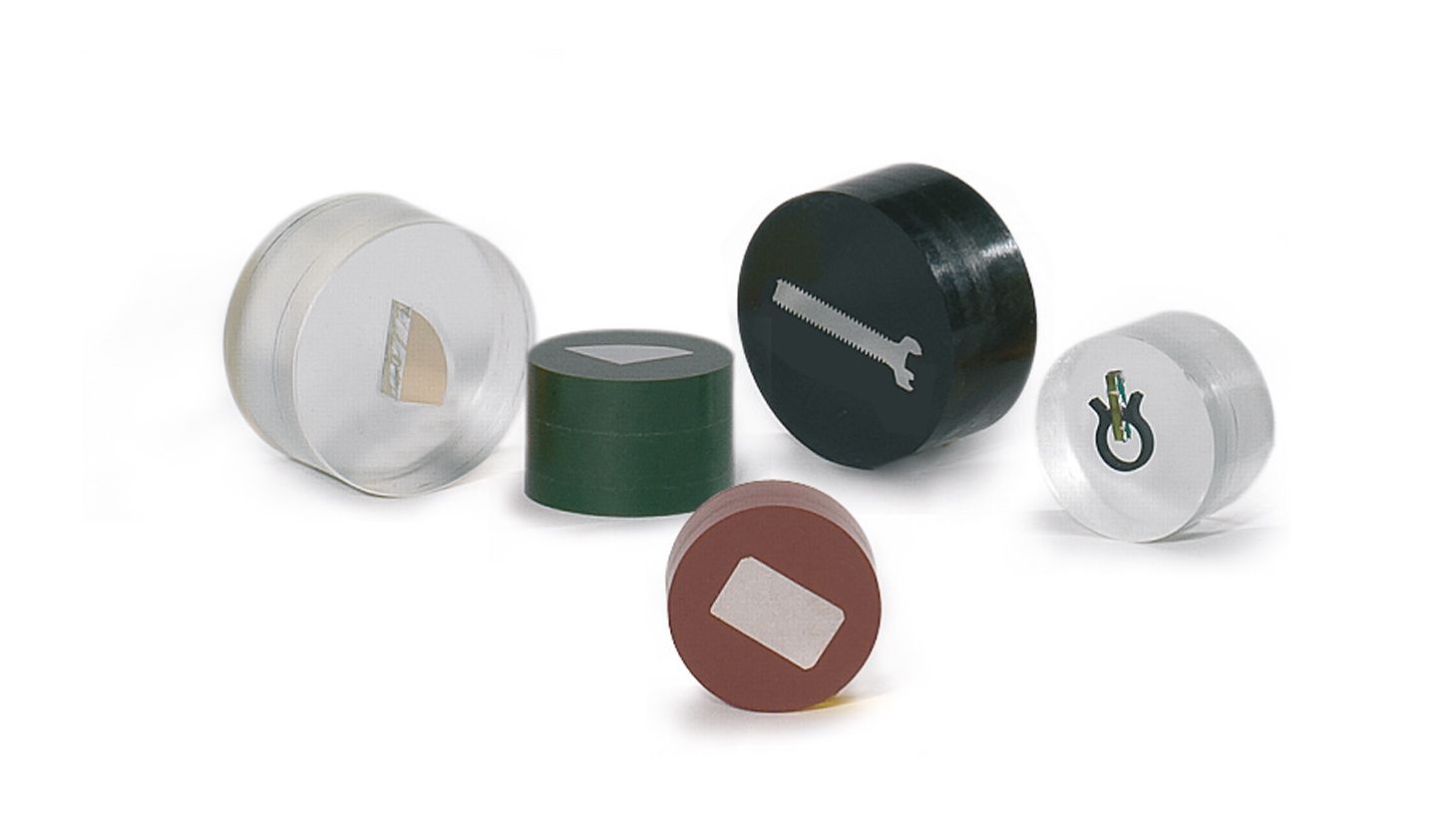

Heating unit & assembly mould

Ø 25.4 (1”), 30, 40, 1’’¼ & 1’’½

- Heating unit – 60 PL2H1 00

- Assembly mould Ø 25,4 mm ou 1” – 60 PL1C1 00

- Assembly mould Ø 30 mm – 60 PL1C2 00

- Assembly mould Ø 40 mm – 60 PL1C4 00

- Assembly mould Ø 1”¼ – 60 PL1C2 10

- Assembly mould Ø 1”½ – 60 PL1C4 10

Heating unit & assembly mould

Ø 50 et 2’’

- Heating unit – 60 PL2H2 00

- Assembly mould Ø 50 mm – 60 PL1C5 00

- Assembly mould Ø 2” – 60 PL1C5 10

Spacers for double mounting

- Spacer Ø 25,4 mm ou 1″ – 60 PL2I1 10

- Spacer Ø 30 mm – 60 PL2I2 00

- Spacer Ø 40 mm – 60 PL2I4 00

- Spacer Ø 50 mm – 60 PL2I5 00

- Spacer Ø 1”¼ – 60 PL2I2 10

- Spacer Ø 1”½ – 60 PL2I4 10

- Spacer Ø 2” – 60 PL2I5 10

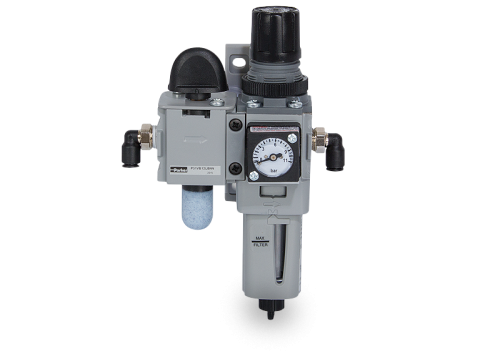

Pressure regulator filter kit for compressed air

Indispensable to preserve the machines from impurities.

Also available with: CUTLAM© 4.0/5.0, PRESSLAM© 1.1, SMARTLAM© 3.0, MASTERLAM© 1.0/1.1/3.0.