The most versatile manual polishing machine

Bidirectional rotation, variable speed and programmable timer

Ø from 200 to 300 mm

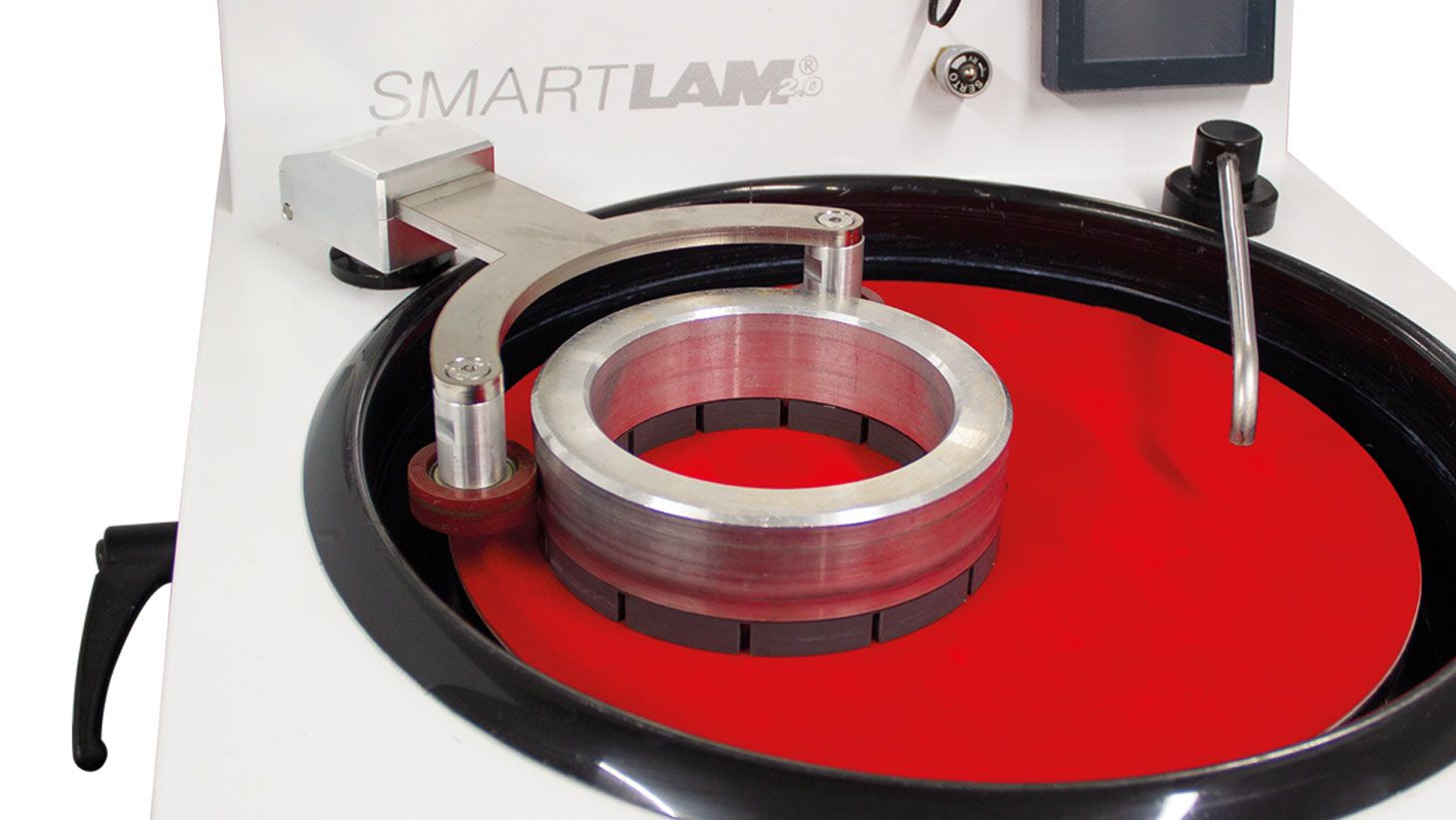

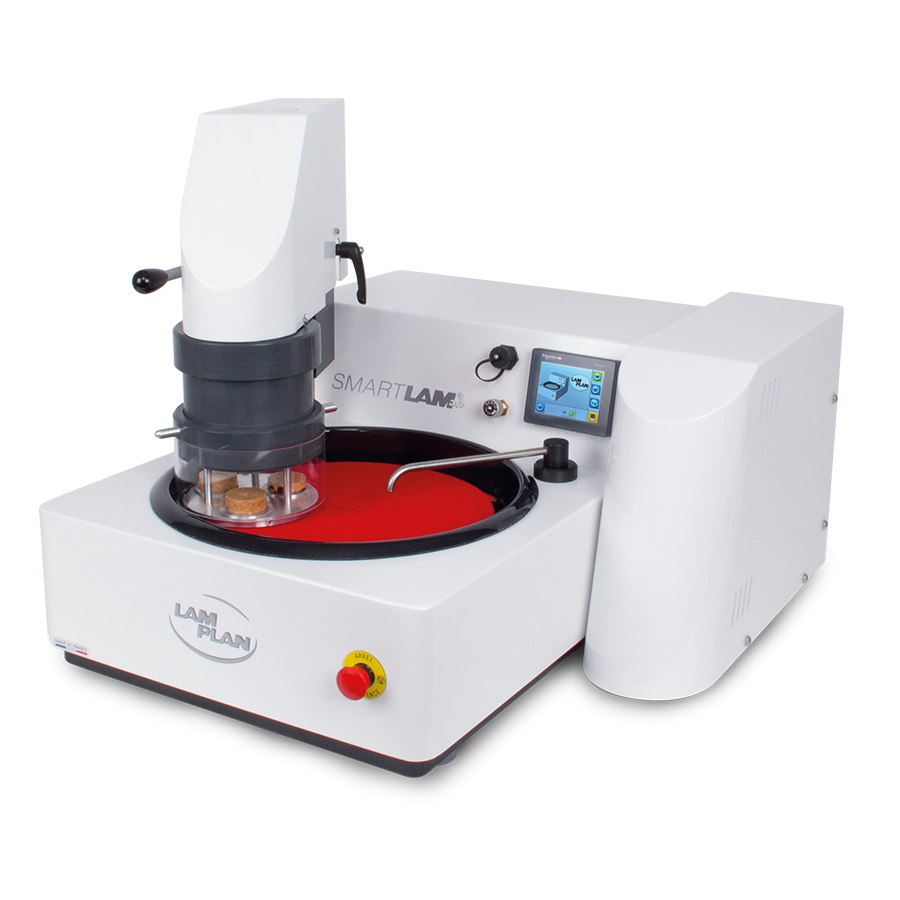

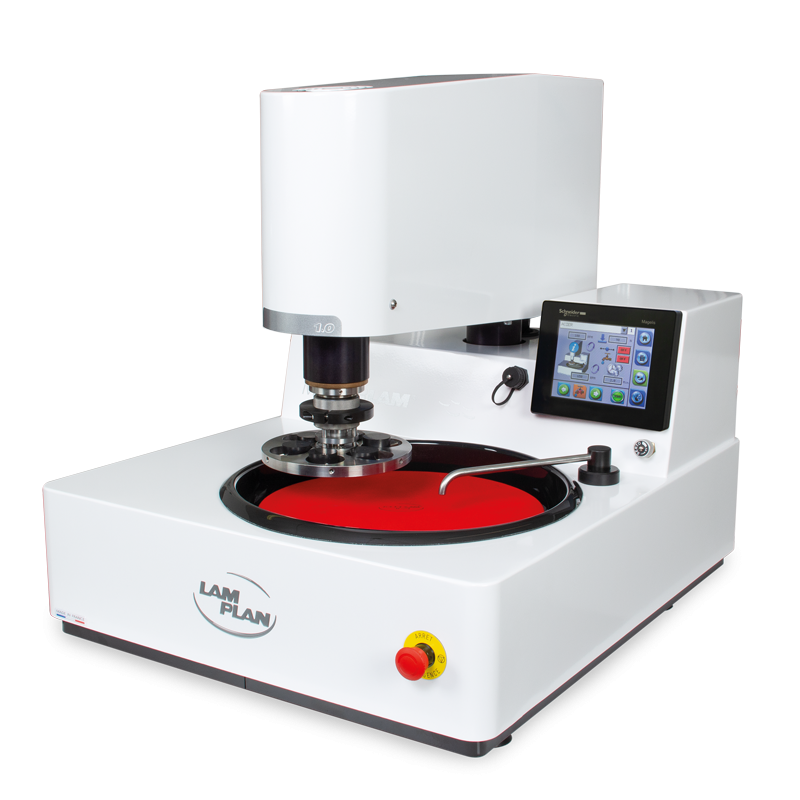

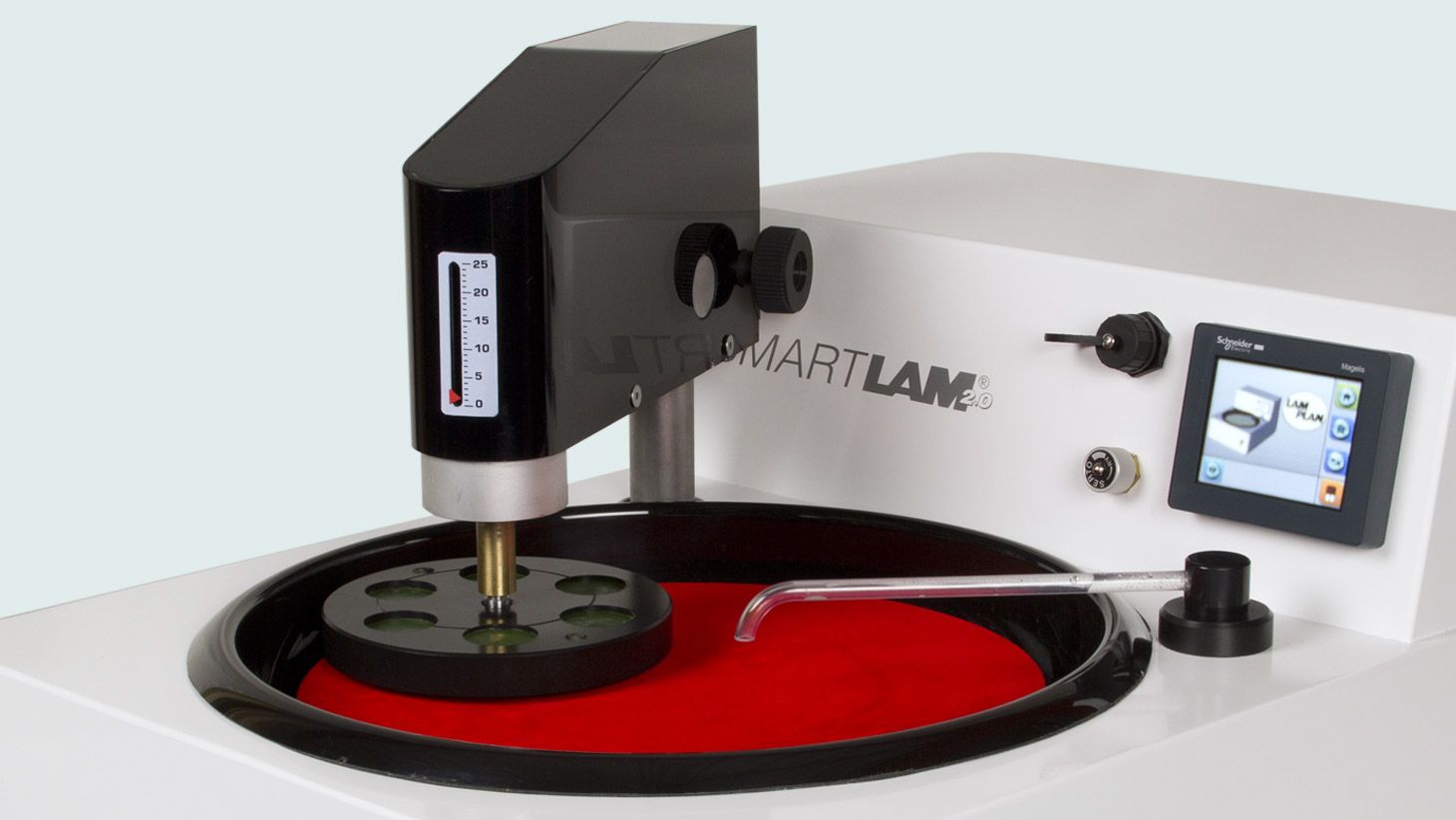

SMARTLAM®2.0

SMARTLAM®2.0 is a polisher that offers you a wide range of possibilities for both manual and semi-automatic polishing, controlled entirely by a colour touch screen with an intuitive interface. The internal memory can store 9 programmes, which can be exported via the USB port.

-

Ø plate capacity200 to 300 mm

-

Plate rotation speed20 to 650 rpm

-

Weight30 kg

-

BodySteel, coated with epoxy paint

The power of the bidirectional rotation, variable-speed, constant -torque motor and the possibility to use plates with a diameter from 200 to 300 mm are exclusive assets that will allow you to face up to all situations encountered in metallographic research polishing.

Evolutive

Thanks to the mechanical pressure head option SPRINGLAM® and the central-pressure holders but also use of the M.M. 909 M programmable dosing unit slaved to the machine, you will have a very efficient, semi-automatic polishing system.

Design and advanced technology

Technical characteristics and equipment

Option: SPRINGLAM® pressure head

Use the SMARTLAM® as a semi-automatic polisher.

Two models are available, classic and low pressure.

SPRINGLAM classic: 0 > 250 N | 60 SL222 00 |

SPRINGLAM low pressure: 0 > 50 N | 60 SL222 10 |

Attachment system for central pressure sample-holder | 59 10110 91 |

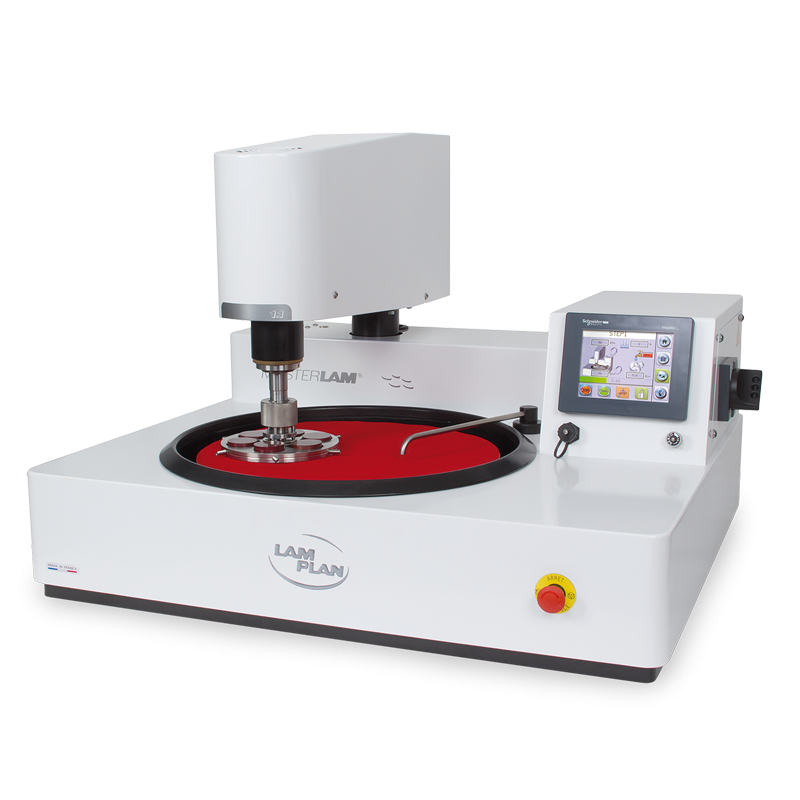

Option: lapping arm for SMARTLAM®2.0

The lapping arm for SMARTLAM®2.0 is an adaptable accessory for holding a lapping ring to prepare the surface of complex-shaped parts.

The system is compatible with rings with an internal diameter of 106 mm.

Lapping arm kit for SMARTLAM® 2.0 | 60 BM223 00 |

PVC lapping ring | 08 83012 00 |

Technical data SMARTLAM®2.0

Plate Capacity | Ø 200 to 300 mm |

Body | Steel, coated with epoxy paint |

Bowl | Removable resin basin for easy cleaning |

Controls | 3,5“ touch screen to control the machine: start/stop, timer, speed and direction of plate, water solenoid valve |

Plate rotation speed | Variable from 20 to 650 rpm |

Rotation | Clockwise / counter-clockwise |

Programming | Loads 9 programs |

Connection | Slave connector for dosing unit |

Water inlet | Removable pipe with flow-rate adjustment and safety solenoid valve |

Power max | 0,75 kW |

Voltage | 230 V – 50 Hz single-phase |

Dim. W x H x D | 450 x 300 x 650 mm |

Weight | 30 kg |

Reference | 60 SL200 00 |

Downloads

Available accessories

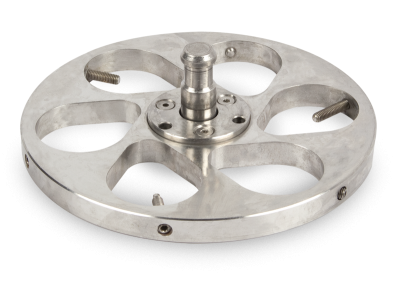

Aluminium plates

- Aluminium plate Ø 200 mm – 08 8270100

- Aluminium plate Ø 230 mm – 08 8270200

- Aluminium plate Ø 250 mm – 08 8270300

- Aluminium plate Ø 300 mm – 08 8270400

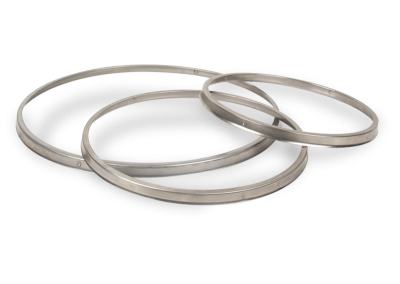

Clamping rings

- Clamping ring Ø 200 mm – 60 SL00290

- Clamping ring Ø 230 mm – 60 SL00190

- Clamping ring Ø 250 mm – 60 SL00490

- Clamping ring Ø 300 mm – 60 SL00690

- Clamping ring Ø 305 mm – 60 SL00790

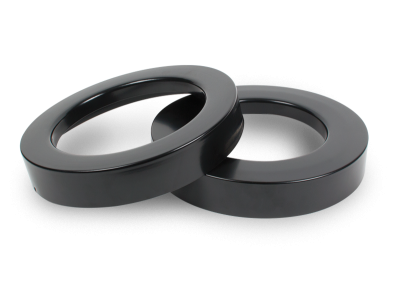

Tank reducers

- Tank reducer Ø 200 mm – 60 ML08090

- Tank reducer Ø 230 mm – 60 ML08290

- Tank reducer Ø 250 mm – 60 ML08190

Anti-splash ring

For MASTERLAM® & SMARTLAM® 2.0

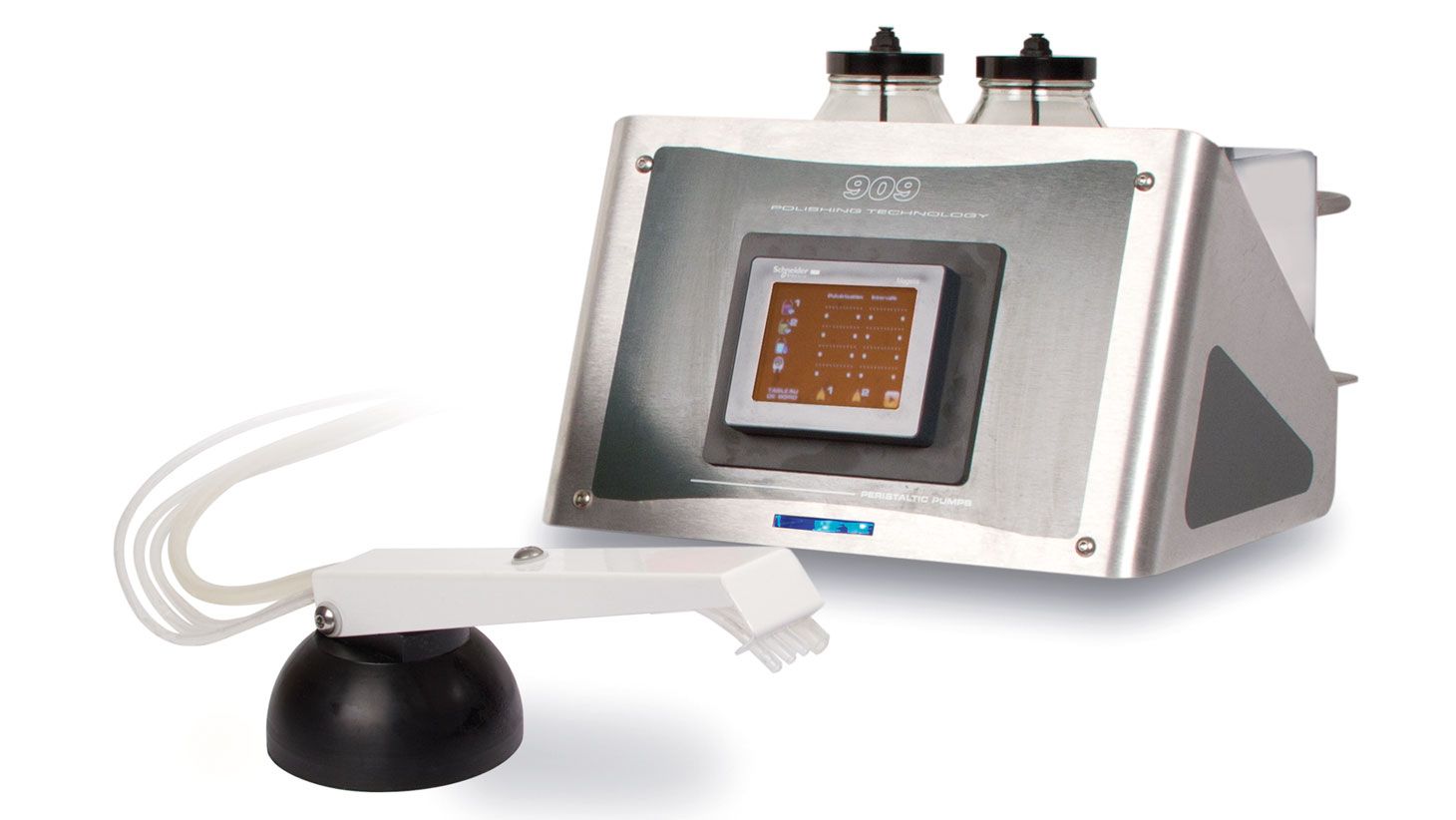

M.M. 909 M dosing unit*

* SMARTLAM®2.0 equipped with the SPRINGLAM®

- Distribution of 3 different liquids.

- Touch screen.

- 3 peristaltic pumps.

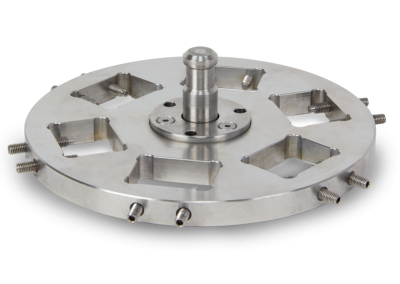

Sample holders central pressure*

* SMARTLAM®2.0 equipped with the SPRINGLAM®

- Ø 119 mm with 6 x Ø 20 to 32 mm water drop cells – 06SMC2000

- Ø 160 mm with 6 x Ø 20 to 40 mm water drop cells – 06MLC1000

- Ø 160 mm with 9 x Ø 30 mm water drop cells – 06MLC3000

- Ø 160 mm with 6 x Ø 40 mm water drop cells – 06MLC4000

- Ø 160 mm with 5 x Ø 50 mm water drop cells – 06MLC5000

Sample holders central pressure with rectangular cells*

* SMARTLAM®2.0 equipped with the SPRINGLAM®

- Ø 160 mm with 3 x rectangular 40 x 70 mm water drop cells – 06MLC1200

- Ø 160 mm with 6 x rectangular 25 x 34 mm water drop cells – 06MLC1400

Levelling plates for central pressure sample holder*

* SMARTLAM®2.0 equipped with the SPRINGLAM®

- Ø 119 mm – 3 mm depth – 06 MLP02 00

- Ø 160 mm – 3 mm depth – 06 MLP01 00