Individual pressure semi-automatic polishing machine

All the mahines and heads fonctions are controlled by the touch screen (speed, pressure, time…)

Control of three peristaltic pumps and 1 outlet to drive an external pump.

Individual pressure 3 cells sample holder,

Variable rotation speed and pneumatic pressure.

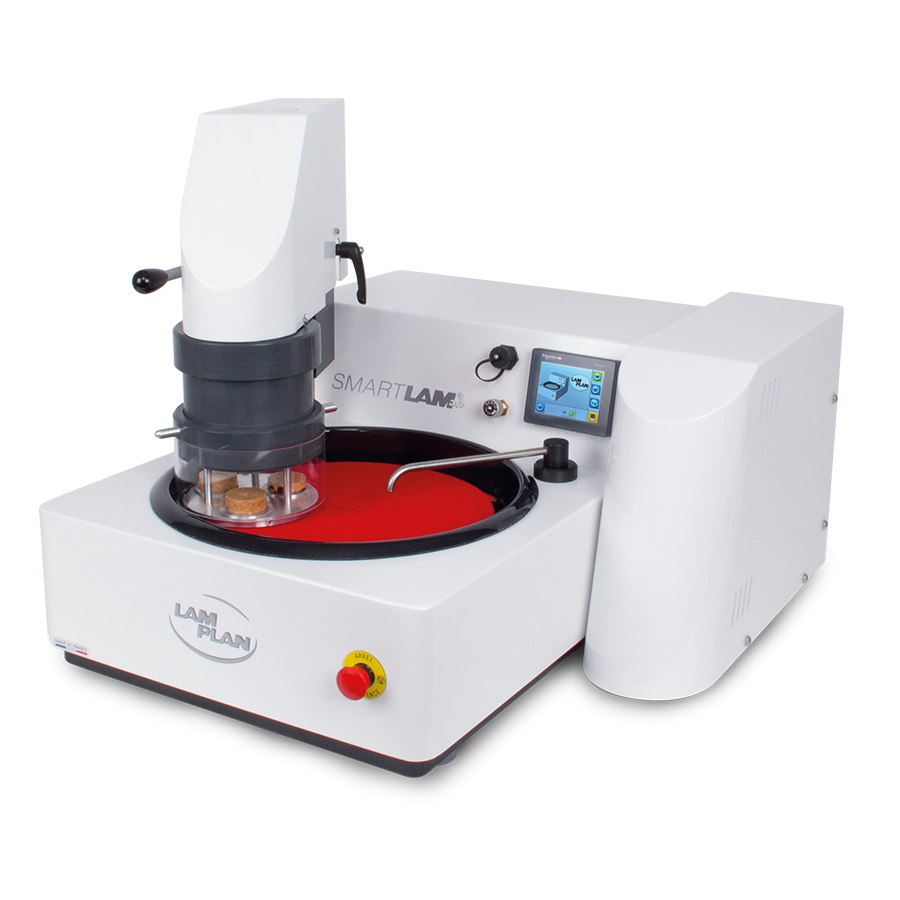

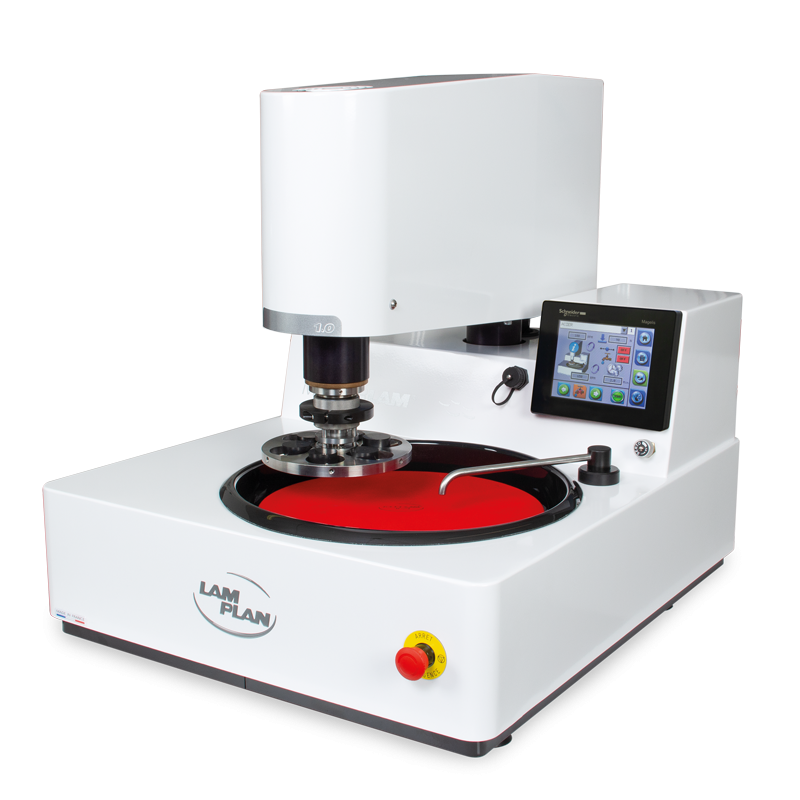

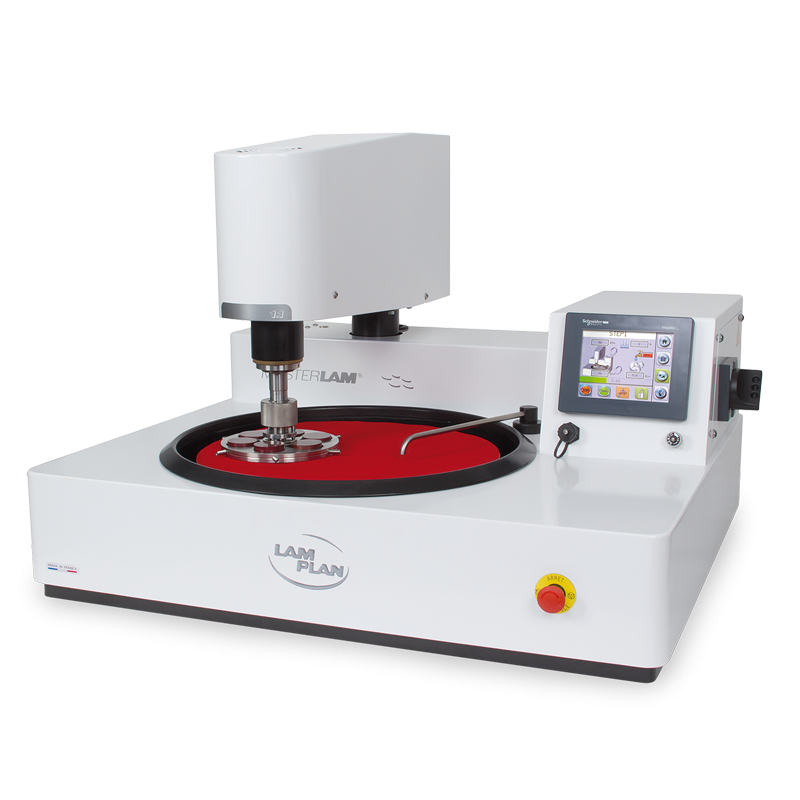

SMARTLAM®3.0

With the SMARTLAM®3.0, LAM PLAN proposes an economic solution in terms of automatic pre-polishing and polishing of metallographic samples.

-

Ø plate capacity200 to 300 mm

-

Plate rotation speed20 to 650 rpm

-

Weight65 kg

-

BodySteel coated with epoxy paint

The SMARTLAM®3.0 is equipped with a new specific motorised head, composed with a 3 cells sample-holder and an individual pneumatic pressure system.

The moto reducer group has a high torque, the speed and the rotation can be set. The individual pneumatic pressure system handled by the electronic proportional valve, assures a great polishing regularity. The pressure applied per sample goes from 5 to 60 N.

The SMARTLAM®3.0 uses the reliable and proven base of the SMARTLAM®2.0 from which it conserves all the assets for a manual use (activation/deactivation of the sample holder head with the touch screen). The plate’s speed and rotation can be set from 20 to 650 rpm.

For more efficiency, you can connect the M.M. 909 M automatic dosing unit to your SMARTLAM® 3.0 and benefit of a very economic and competitive set.

The automatic motorised head compactness is due to its strategically placed power supply on the side of the machine. The head rotates to free the workspace and allows the easy change of the polishing support and the cleaning of the plate and bowl.

All the functions accomplished by the machine or the head are controlled by the screen. The programs can be stored in the intern memory.

To avoid the risk of jamming, SMARTLAM®3.0 is now fitted as standard with a passive sample holder protection system. This consists of a transparent polycarbonate cover over the moving parts.

Design and advanced technology

Technical characteristics and equipment

Technical data of the head

-

Capacity3 samples Ø 25,4 to 50 mm

(on Ø 200 mm plate 3 samples Ø 30 mm max.) -

BodySteel coated with epoxy paint

-

ControlsColour touch screen (3“): controls the machine and the head

-

Sample holder rotation speedVariable from 10 to 150 rpm

-

RotationClockwise / counter-clockwise

-

PressureIndividual, pneumatic, variable from 5 to 60 N

-

ProgrammingLoads 9 programs

-

Power maxMoto reducer with high torque

-

PositioningManual, with indexable handle

-

Positioning and locking in heightManual, raising/lowering of the head with a lever, locking with knobe

-

Security

Sample holder protection system

Technical data SMARTLAM®3.0

Plate capacity | Ø 200 to 300 mm |

Body | Steel coated with epoxy paint |

Bowl | Removable resin basin for easy cleaning |

Controls | 3,5“ touch screen to control the machine: start/stop, timer, speed and direction of plate, water solenoid valve |

Plate rotation speed | Variable from 20 to 650 rpm |

Rotation | Clockwise / counter-clockwise |

Programming | Loads 9 programs |

Connection | Slave connector for dosing unit |

Water inlet | Removable pipe with flow-rate adjustment and safety solenoid valve |

Power max | 0,75 kW |

Voltage | 230 V – 50 Hz single-phase |

Pneumatic feed | 6 bars, filtered 50 µm |

Dim. W x H x D | 580 x 570 x 670 mm |

Weight | 65 kg |

Reference | 60 SL220 00 |

Downloads

Available accessories

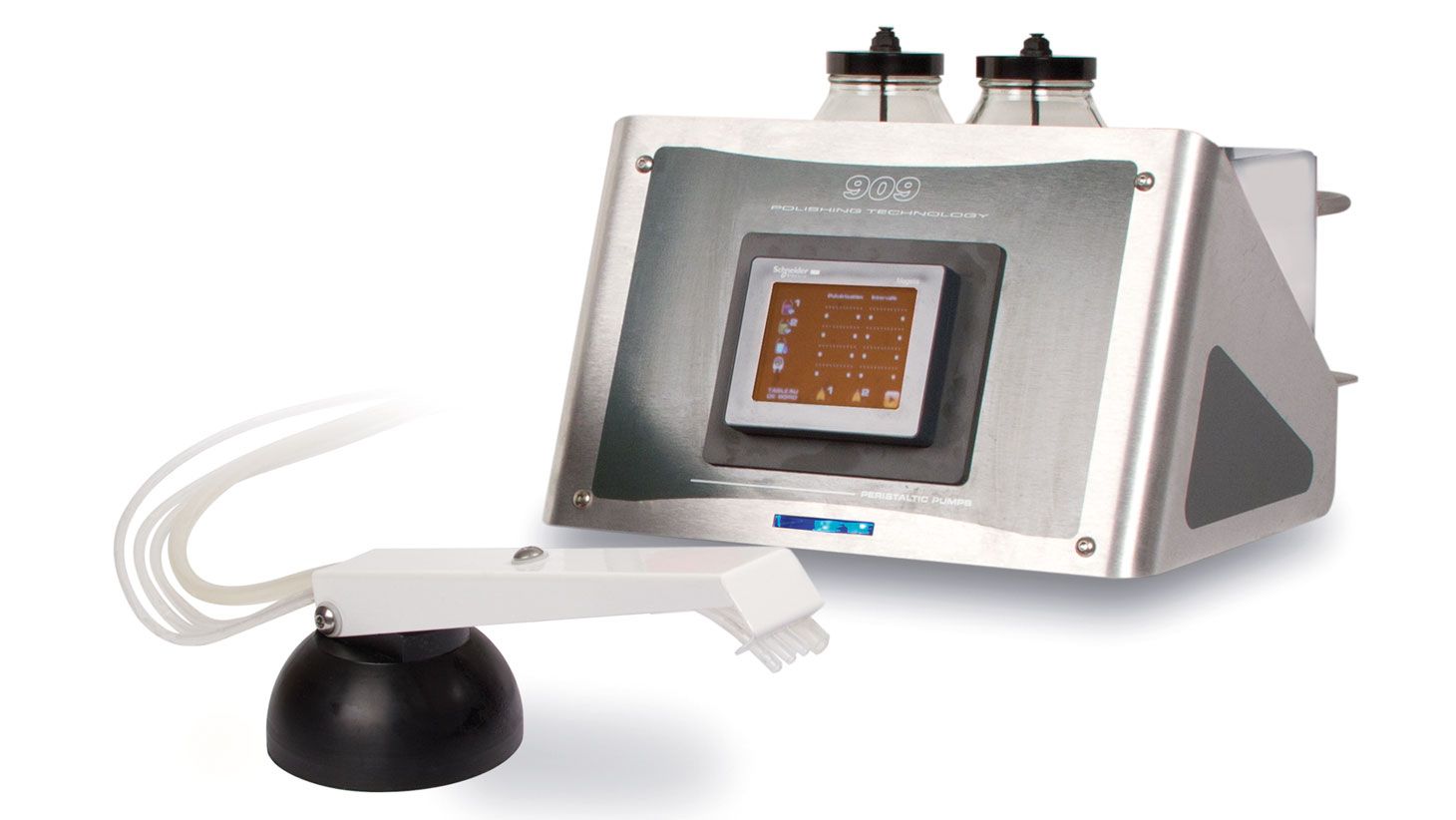

M.M.909 M dosing unit

For even greater efficiency, you can combine the SMARTLAM®3.0 with the M.M.909 M automatic dosing unit, creating an ultra-versatile and highly competitive automatic polishing system.

- Programmed distribution of 3 different liquids.

- Control by color touch screen.

- 3 peristaltic pumps, with 1 outlet to drive an external pump.

Aluminium plates

- Aluminium plate Ø 200 mm – 08 8270100

- Aluminium plate Ø 230 mm – 08 8270200

- Aluminium plate Ø 250 mm – 08 8270300

- Aluminium plate Ø 300 mm – 08 8270400

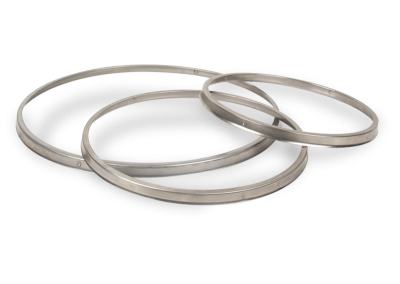

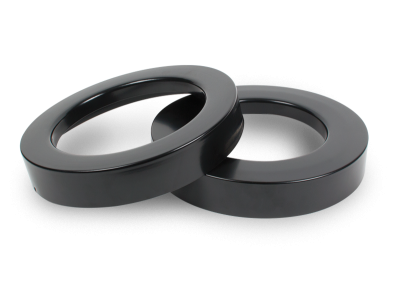

Clamping rings

- Clamping ring Ø 200 mm – 60 SL00290

- Clamping ring Ø 230 mm – 60 SL00190

- Clamping ring Ø 250 mm – 60 SL00490

- Clamping ring Ø 300 mm – 60 SL00690

- Clamping ring Ø 305 mm – 60 SL00790

Tank reducers

- Tank reducer Ø 200 mm – 60 ML08090

- Tank reducer Ø 230 mm – 60 ML08290

- Tank reducer Ø 250 mm – 60 ML08190

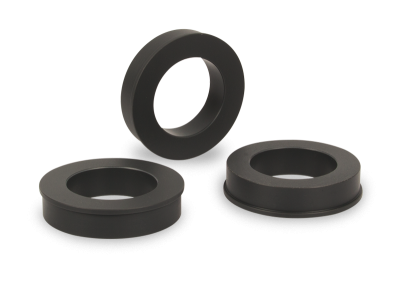

Reducer rings

- Kit 6 x Ø 40 mm reducer rings – 06MLIK500

- Kit 6 x Ø 30 mm reducer rings – 06MLIK200

- Kit 6 x Ø 25,4 mm reducer rings – 06MLIK110

- Kit 6 x 1-1/4″ reducer rings – 06MLIK310

- Kit 6 x 1-1/2″ reducer rings – 06MLIK410