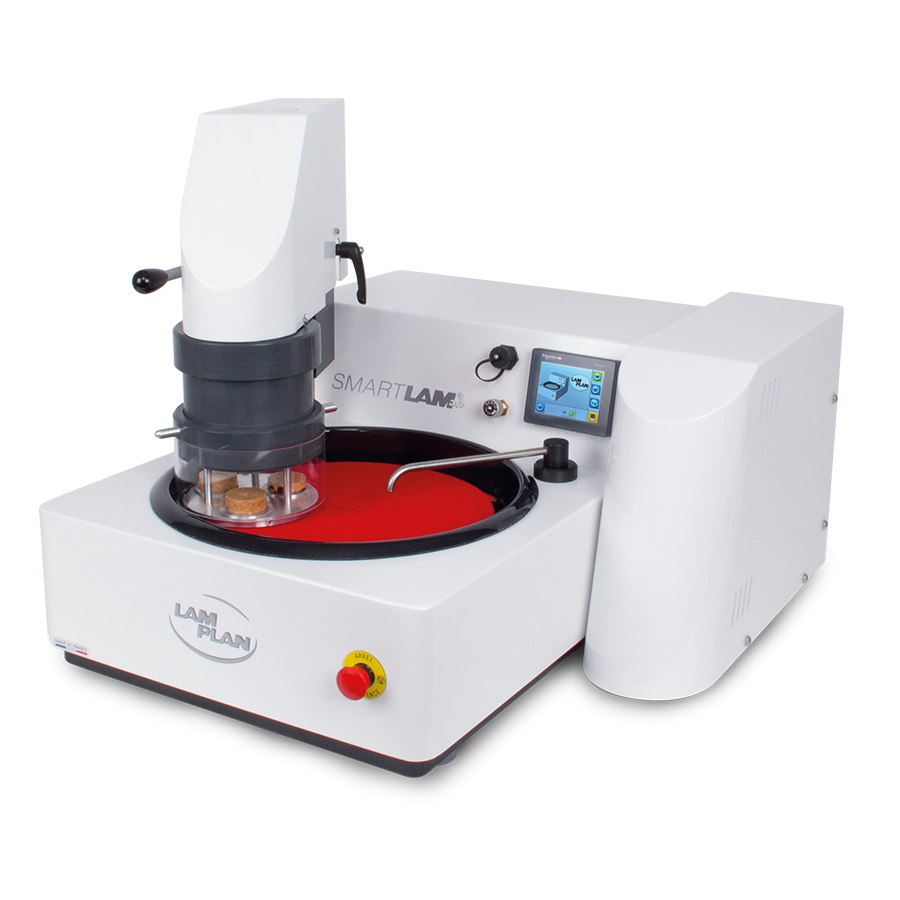

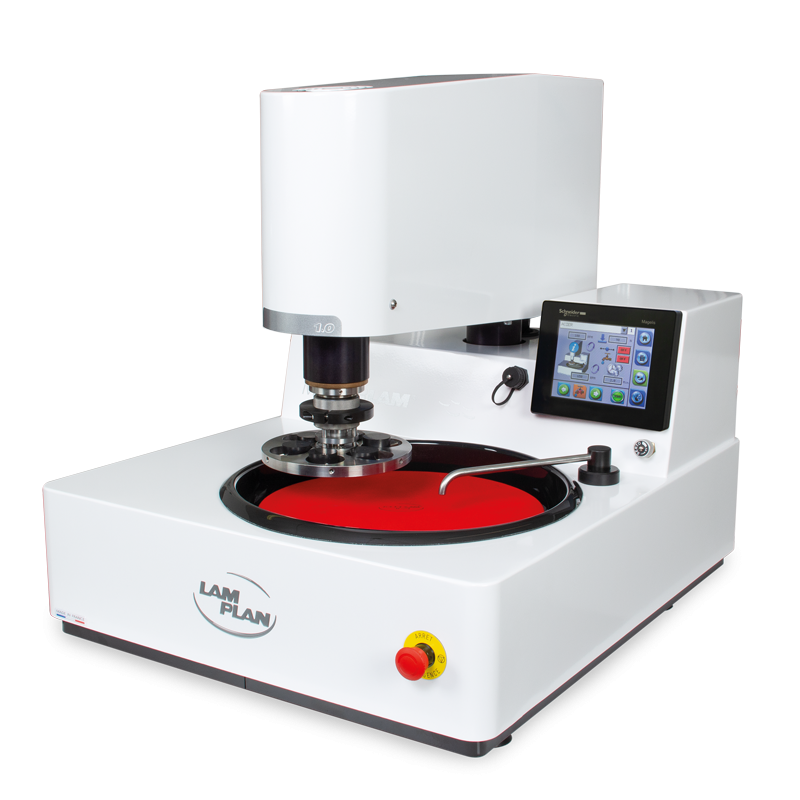

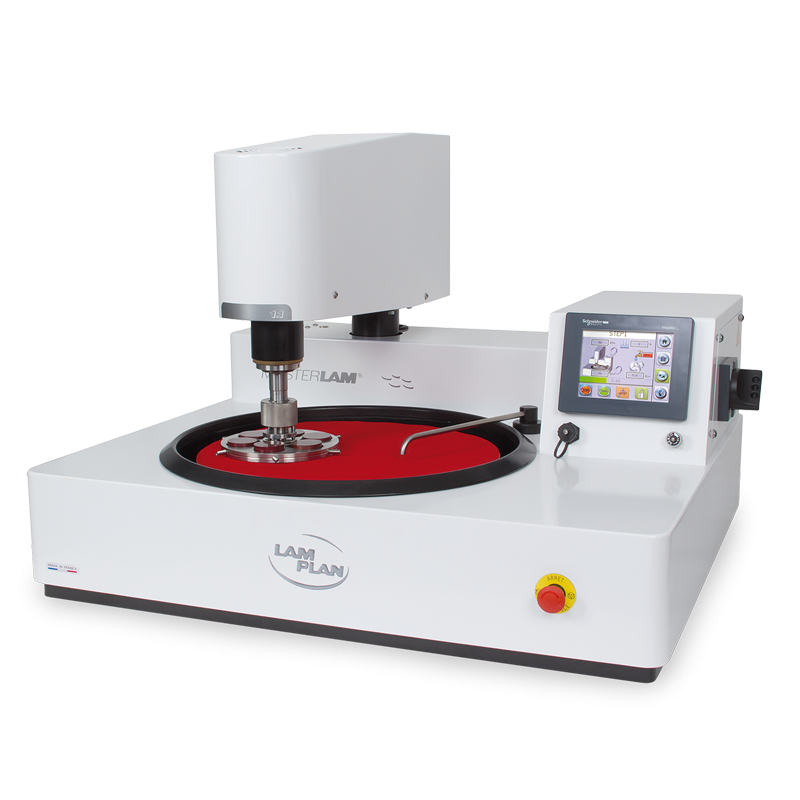

RECTILAM®2.0

When the prepolishing phase demands a high level of effectiveness and precision the RECTILAM®2.0 is the answer. This machine is particularly productive in the preparation of coated or raw samples by high speed prepolishing. Several parts can be installed on the central pressure sample holder. Large parts can also be treated individually.

-

Wheel Ø356 mm

-

Rotational speed1000 to 3000 rpm

-

Applicable charge10 to 550 N

-

Stock removal0,1 mm to 1 mm

The principle of high speed prepolishing on stone enables significant material removal and unrivalled flatness without rounding the edges.

The single block design and rigidity of the RECTILAM®2.0 avoids vibration which is detrimental to the surface condition. In order to ensure significant and even removal of material, a reconditioning system automatically follows each stage of polishing.

The prepolishing system and the sample holder are connected to the same mechanical arm which guarantees precision.

The RECTILAM®2.0 is supplied with an integral security hood. The assembly includes a closed-circuit lubricating filtration system integrated into the machine as well as a spray-tap for cleaning.

The RECTILAM®2.0’s unique feature is its 2 axis principle.

The Z axis deals with the motorised rise and fall of the reconditioning tool and the pressurisation of the sample carrier.

The R axis enables precise positioning of the sample holder in relation to the grinding wheel in order to make to most of the available abrasion surface.

During the start cycle the starting point of the sample/grinding wheel is automatic. The stock removal is continuously managed. The real-time display shows the operator if the rectification settings entered are appropriate.

All parameters are managed and clearly shown on the 5.7’’ touchscreen with graphic display.

Design and advanced technology

Technical characteristics and equipment

Downloads

Technical data RECTILAM®2.0

Grinding wheel diameter | Ø 356 mm |

Control | By 5.7 inch touchscreen and joystick |

Grinding wheel speed | 1000 to 3000 rpm. |

Sample holder speed | 20 to 150 rpm. |

Applied force | 10 to 550 N |

Sample holder size | Ø 210 mm max |

Conditioning wheel specifications | Configurable pass depth and diamond feed rate |

In cycle reconditioning mode | Automatic – customisable frequencies |

Stock removal range | 0,1 mm to 1 mm |

Measurement precision | 0,02 mm |

Work zone lighting | Enclosed LED |

Grinding wheel motor power | 3,8 kW |

Sample holder motor power | 0,25 kW |

Noise level | 70 dB |

Voltage | 400 V-50 Hz three-phase + neutral |

Body | Powder-coated steel |

Dim. L x H x P | 900 x 1620 x 1000 mm (H. cover open : 1850 mm) |

Weight | 450 kg |

Reference | 60 RL200 00 |

Available accessories

Grinding wheel AL2O3 – Grain 60

For grinding of soft, ductile materials

Lubricant : water

Ø: 355 mm

Grinding wheel SiC – Grain 150

For grinding of all materials >HV200

Lubricant : water

Ø: 355 mm