Grinding and pre-polishing discs CAMEO®DISK Silver, Gold & Rhodium

The CAMEO®DISK Silver, Gold & Rhodium discs are non-diamond grinding discs developed to be used with Bio DIAMANT® abrasive products (free abrasives.)

CAMEO®DISK Silver, Gold & Rhodium in action

Watch the video to see how to dress the CAMEO®DISK Silver, Gold and Rhodium with the appropriate dressing tool.

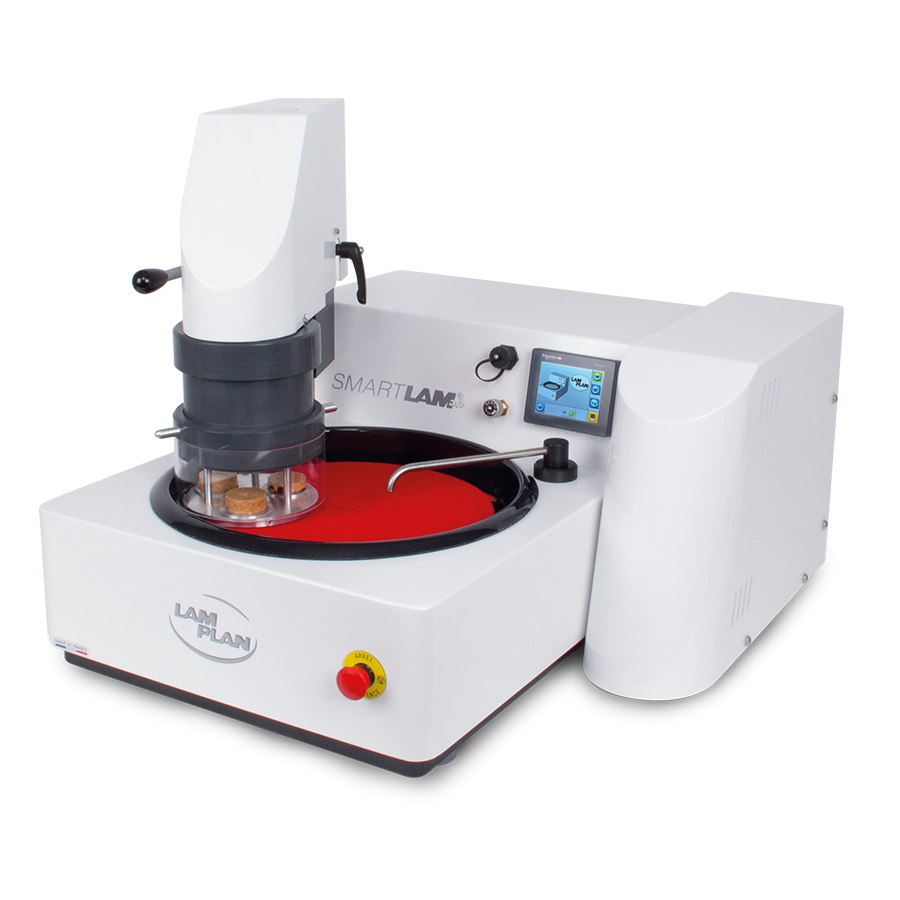

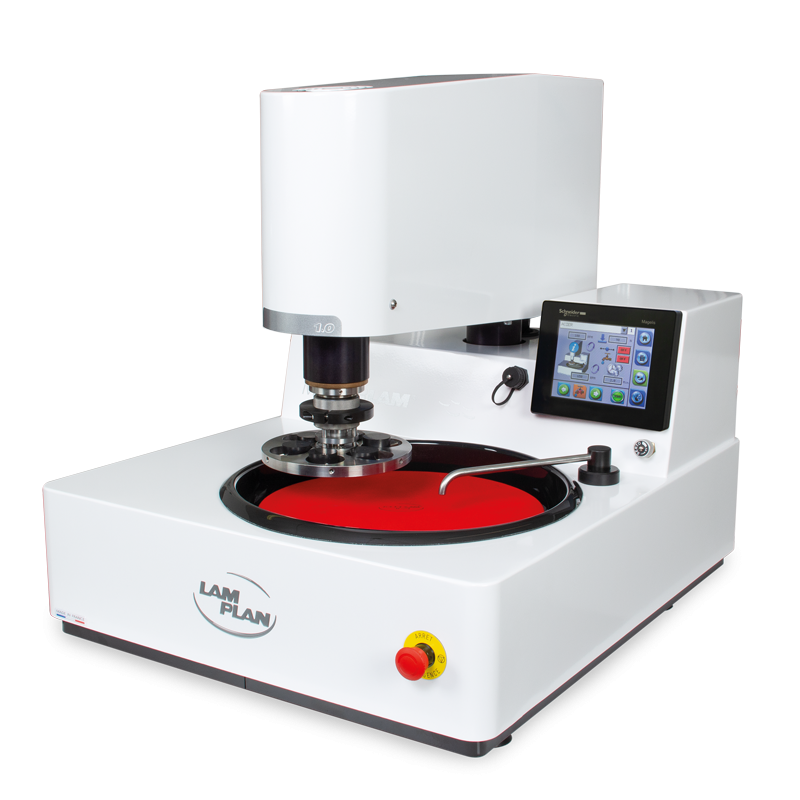

Grinding and polishing are key steps in the preparation of a metallographic sample. It is the quality of these steps which will condition and optimise the rest of the process.

Grinding and polishing are key steps in the preparation of a metallographic sample. It is the quality of these steps which will condition and optimise the rest of the process.

At the end of the grinding step, the sample’s aspect must be uniform and regular without altering the inherent flatness and the material.

The CAMEO®DISK’s performances in terms of stock removal reduce the work time on the part, thereby guaranteeing the sample’s inherent flatness, an indispensable condition to succeed with your metallographic analyse.

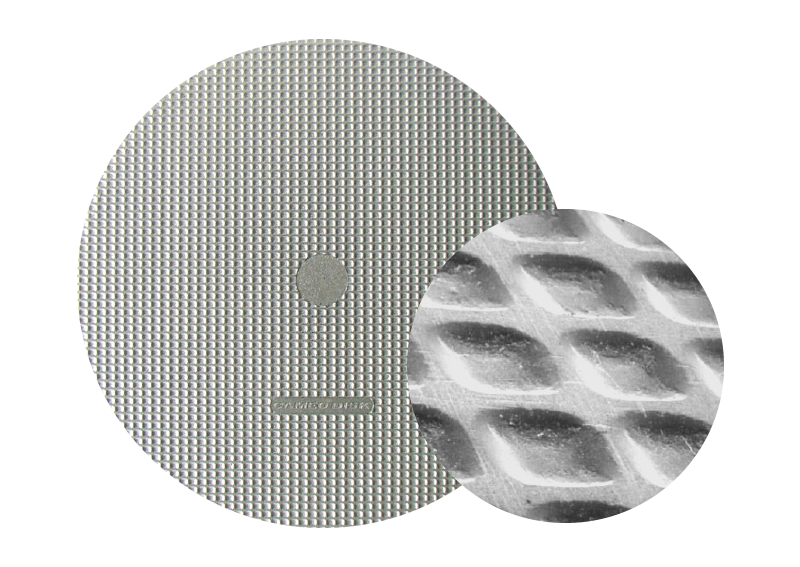

A patented honeycomb cell structure

Stock removal

The CAMEO®DISK honeycomb cell structure allows decreasing the surface in contact with the sample to be polished. The pressure required to grind the sample is much less than that generally applied during the use of a solid disc. The equipment is less stressed and the risks of tearing out the grinding disc are significantly reduced.

Reproducibility

The profile of the honeycomb cells was specially designed to optimise the circulation of the lubricant from one cavity to another.

The abrasion residues are evacuated, guaranteeing a constant abrasive power and therefore a regularity of the result throughout the grinding and polishing steps.

Preparation quality

For a process usually performed with several SiC abrasive papers, LAM PLAN proposes you a single, reusable disc: the CAMEO®DISK. Contrary to SiC abrasive papers, CAMEO®DISK constant abrasion prevents the formation of deep disturbed layers during the first few seconds of grinding.

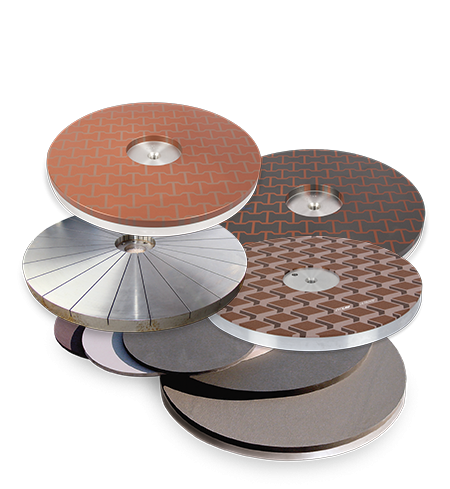

CAMEO®Disk Silver, Gold & Rhodium

Prepolishing discs for metallography.

Prepolishing in metallography removes the coarse scratches from the rough grinding steps and prepares the samples for final polishing.

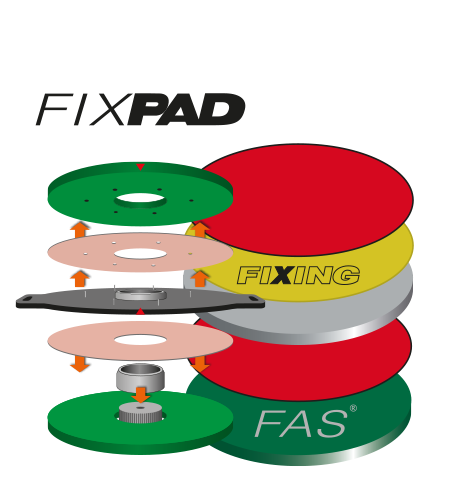

CAMEO®DISK are composite pads developed for prepolishing metallographic samples. They are used with BIO DIAMANT® NEODIA® abrasive liquids.

The patented CAMEO®DISK honeycomb structure allows the uniform distribution of the periodically pulverised diamond abrasive suspension.

The use of the abrasive suspension is optimised, thereby reducing the diamond product’s consumption.

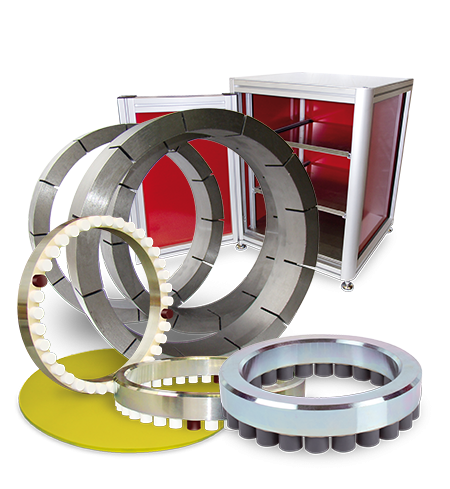

CAMEO®DISK are available in magnetic or self-adhesive versions and can be associated with the various LAM PLAN fixing accessories.

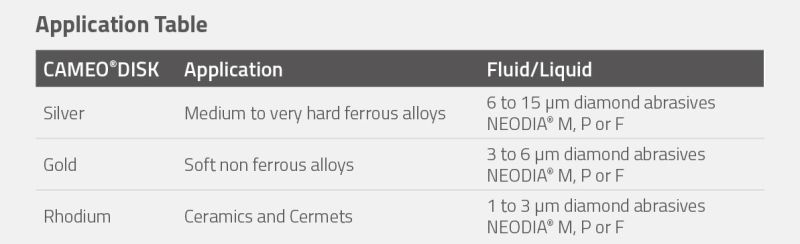

There are three variants of CAMEO®DISK designed with differing hardness suited for different types of material prepolished.

Range CAMEO®Disk Silver

Application: Medium to very hard ferrous alloys.

Abrasive liquid: 6 to 15 μm diamond abrasives NEODIA® M, P or F.

| Boxes of 2 pieces + 1 dressing tool | Self-adhesive | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA120 20 | 09 CA520 20 |

| 250 | 09 CA120 40 | 09 CA520 40 |

| 300 | 09 CA120 50 | 09 CA520 50 |

Range CAMEO®Disk Gold

Application: soft non ferrous alloys.

Abrasive liquid: 3 to 6 μm diamond abrasives NEODIA® M, P or F.

| Boxes of 2 pieces + 1 dressing tool | Self-adhesives | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA130 20 | 09 CA530 20 |

| 250 | 09 CA130 40 | 09 CA530 40 |

| 300 | 09 CA130 50 | 09 CA530 50 |

Range CAMEO®Disk Rhodium

Application: ceramics and cermets.

Abrasive liquid: 1 to 3 μm diamond abrasives NEODIA® M, P or F.

| Boxes of 2 pieces + 1 dressing tool | Self-adhesives | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA100 20 | 09 CA500 20 |

| 250 | 09 CA100 40 | 09 CA500 40 |

| 300 | 09 CA100 50 | 09 CA500 50 |

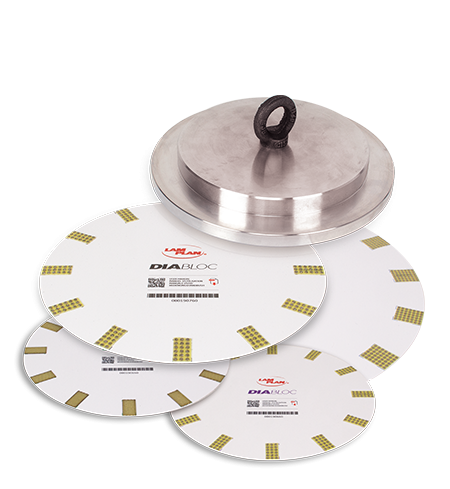

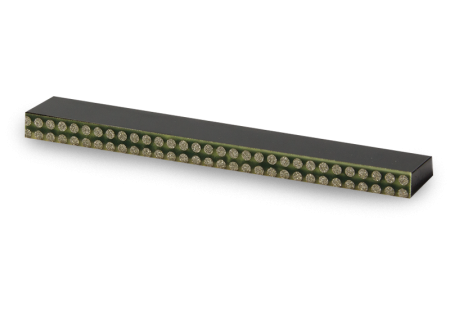

Dressing tools

Diamond tools for CAMEO®DISK Silver, Gold & Rhodium

Dimensions : 100 x 15 x 5 mm

Guidance

In order to guarantee constent results, the CAMEO®DISK have to be periodically dressed by appropriate abrasive dressing tool.